Controls and Automation

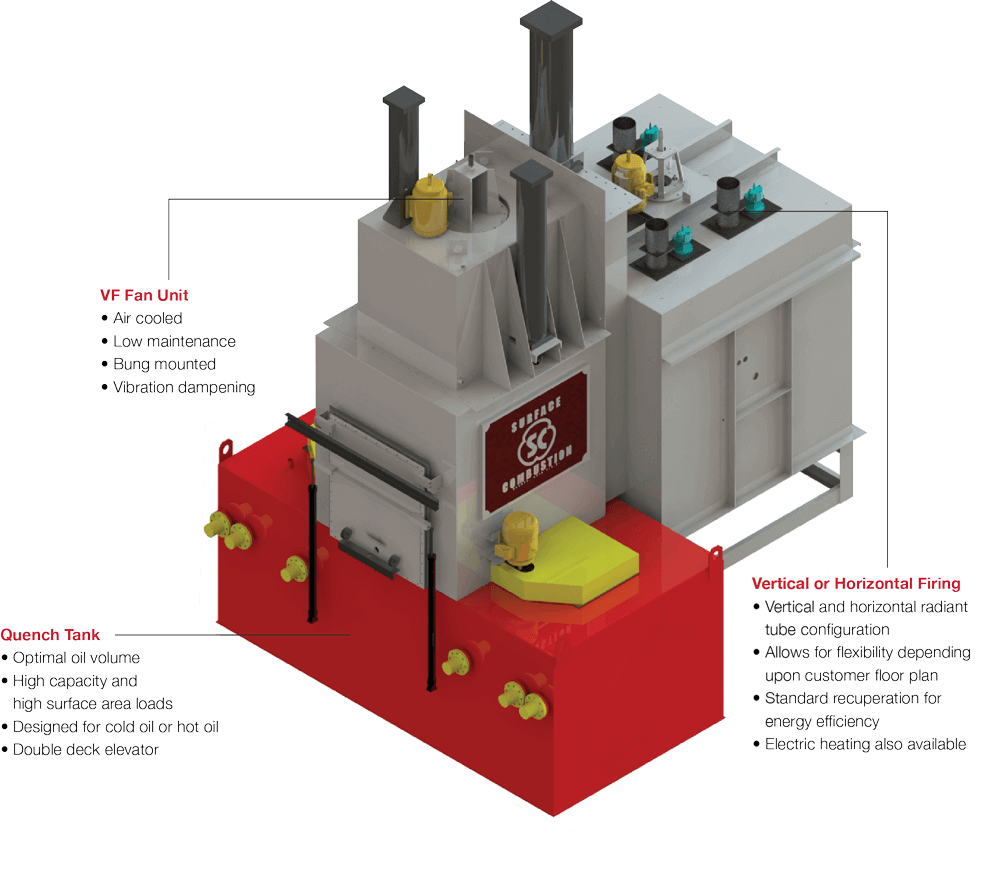

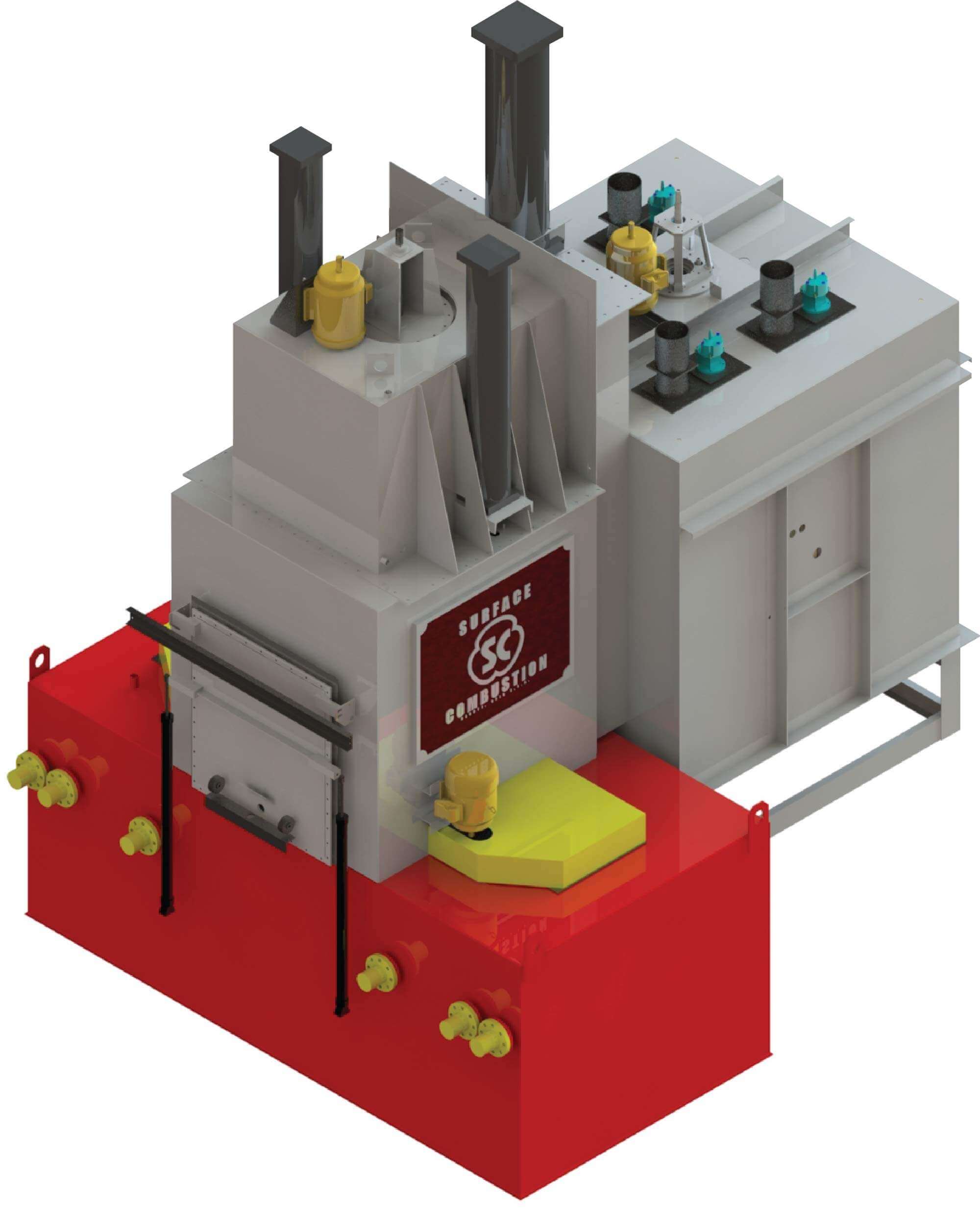

Available in 6 standard effective work sizes and 4 different configurations, an Allcase line can be fully automated with companion equipment to process loads from start to finish.

Handling System Options:

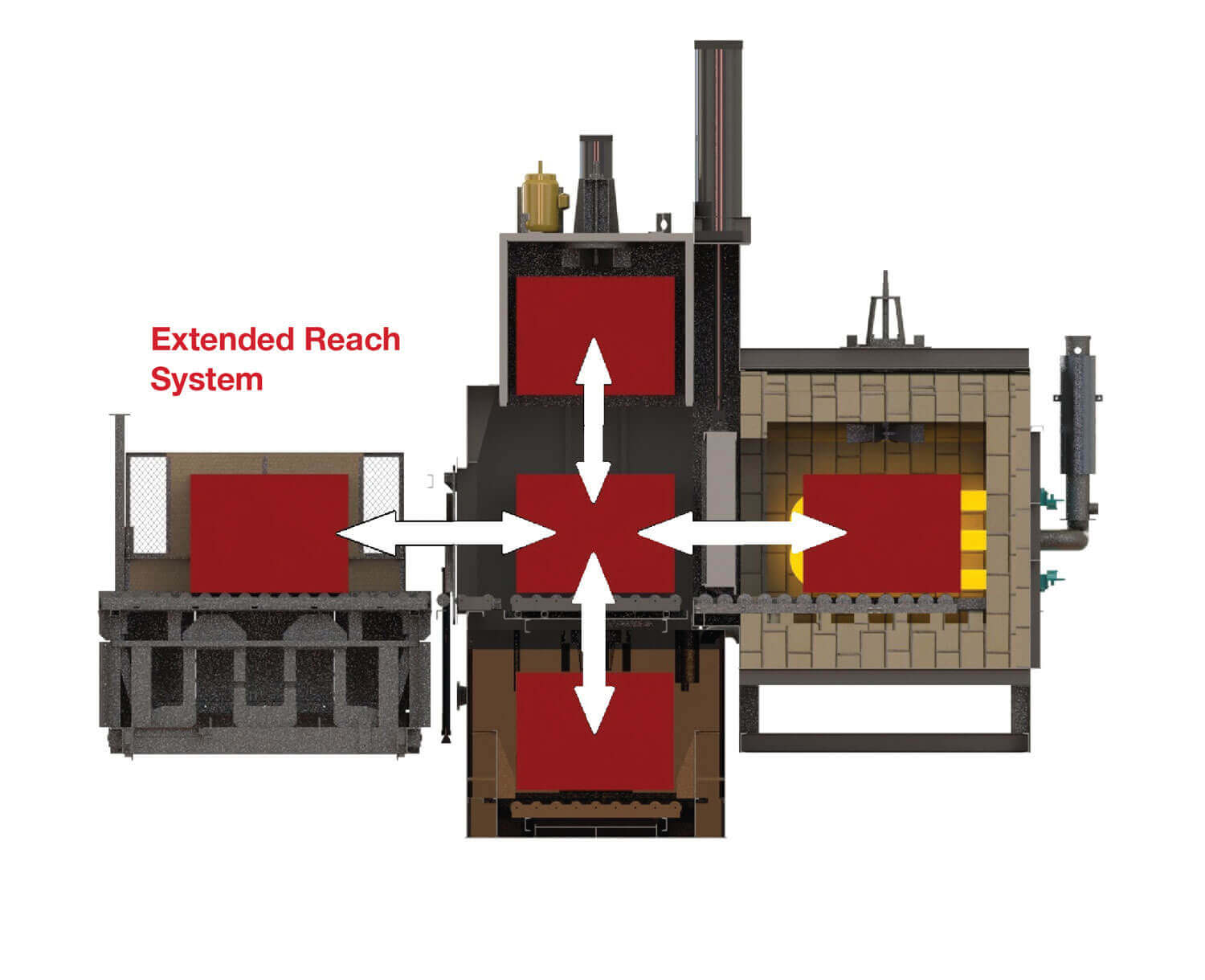

Extended Reach™

- Handler system on charge car or charge table moves the load into the vestibule, to/from the heating chamber and from the vestibule.

- Elevator moves load to/from quench tank and optional top cool.

- All motions are operator initiated.

System #1™

- Operator initiated handler system on charge car or charge table moves the load to/from the vestibule.

- Automatic rear handler system moves the load to/from the heating chamber.

- Automatic elevator moves load to/from quench tank and optional top cool.

Push/Push

- Standard operator initiated or optional automatic loading of charge vestibule and heating chamber with an Extended Reach charge car or charge table.

- Automatic rear handler system moves the load from the heating chamber.

- Automatic elevator moves load to/from quench tank and optional top cool.

- Standard operator initiated or optional automatic unloading of charge vestibule.

- Provides quickest quench transfer time – ideal for thin parts.

- ShuttleTrac™ automated charge car can be paired with fully automatic handling system.

cycle

cycle operation

operation hours per year

hours per year available space

available space operating temperature range

operating temperature range heat source

heat source