Presenting Surface Combustion’s Vacuum Furnace Options

Power Convection: The Rugged Industry Workhorse

BEST FOR: Tool Steels, Stainless Steels, Fuel system components, Medical, Electronics and Instrumentation

- Robust Construction & Safety: Engineered for durability and reduced loading risks.

- Efficient Heat Transfer: Rapid, uniform heat transfer and efficient convection cooling for small and large workpieces.

- Versatile & Customizable: Available in 2-6-bar and up to 10-bar designs, with rugged all graphite hot zones.

- Vacuum Level: 2, 6, 10 bar

- Temperature Range: 1000°F to 2400°F

- Ideal Industries: Automotive, Tooling, Molds and Dies, Medical

VacuDraw Tempering: Industry’s First Low Temperature, Cost-Effective Solution

BEST FOR: Copper, Tool Steels, Stainless Steels, Alloy Steels

- Cost Savings: More profitable cycles with significant cost advantages.

- Improved Efficiency: Convection heating slashes floor-to-floor time, optimizing production.

- Enhanced Flexibility: Supports various atmospheres, processes bright loads without a diffusion pump.

- Vacuum Level: 20 microns. Heating and cooling up to 2 Bar

- Temperature Range: 350°F to 1400°F

- Ideal Industries: Automotive, Commercial, Tool & Die, Agriculture, Off Road, Aerospace, Electrical Components

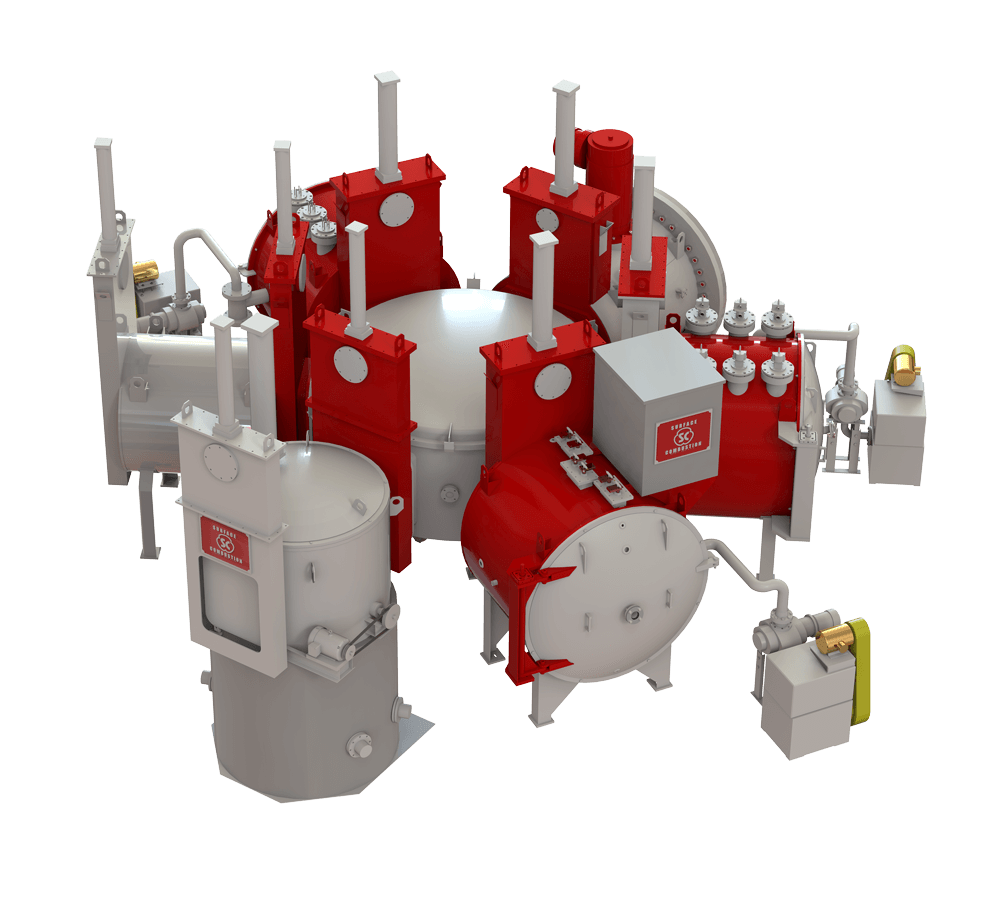

Cloverleaf Vacuum: Flexibility Meets Advanced Technology

BEST FOR: All materials including carburizing grades, hardening grades requiring oil quenching or gas quenching

- Versatile Heating Options: Gas-fired or electrically heated chambers cater to cost effective heating sources.

- Advanced Automation: Precision control with central turret for streamlined material handling.

- Reliable & Maintainable: Isolated maintenance capability ensures uninterrupted operation. Chambers can be opened to atmosphere for inspections or servicing while the system is still in operation.

- Vacuum Level: 20 Microns, Gas Quench Pressure up to 20 Bar or Oil Quench

- Temperature Range: 1000°F to 1800°F for Carb Chamber. 1000°F to 2400°F for High Purity High Temperature Chamber

- Ideal Industries: Agriculture, Off Road, Racing and High Performance, Tool and Die

Multi-Chamber: Engineered for Reliability and Efficiency

BEST FOR: Tool steels, automotive fuel systems, stainless steels, low temperature vacuum processing of hard to keep bright stainless steels, including all materials requiring oil or gas quenching

- Hot Zone Integrity: Maximum hot zone integrity because the heating chamber stays under vacuum and at temperature at all times. Outside humidity and contamination never enters the hot zone while processing.

- Flexible Quenching: Gas or oil quenching capabilities meet diverse vacuum processing requirements.

- Enhanced Cooling: Superior cooling performance for increased productivity, higher part hardness, and faster turnaround

- Versatility in Application: Engineering for heavy loads and high production lots.

- Direct-Fired Solutions: High velocity burners for fast, uniform heating.

- Vacuum Level: 20 microns, Gas Quench Pressure up to 2 Bar or Oil Quench

- Temperature Range: 1000°F to 2400°F

- Ideal Industries: Automotive, Aerospace, Oil & Gas, Tool & Die

Vacuum Allcase: Industry’s Leading Batch Integral Quench Furnace

BEST FOR: Through Hardening, Carburizing, Carbonitriding, Annealing, Ferritic Nitrocarburizing

- Versatile Processing: Handles multiple heat treating processes in one furnace.

- Advanced Quenching: Automatic transfers to various quenching media under protective atmospheres to prevent oxidation.

- Enhanced Features: Larger capacities, improved insulation, and advanced control systems.

- Automation and Compatibility: Equipped for automated processing with adaptable batch systems for diverse workpieces.

- Vacuum Level: 20 Microns, Oil Quench Oil (No Pressure or Bar)

- Temperature Range: 1000°F to 1950°F

- Ideal Industries: Automotive

Softvac Vacuum Furnace: Pioneering Hot Wall Vacuum Technology

BEST FOR: Annealing, Hardening, Low Pressure Carburizing, Stress Relieving

- Enhanced Efficiency: Features hot wall technology to reduce thermal loss and improve temperature and case depth uniformity.

- High-Temperature Capability: Reaches up to 1975°F, supporting high-temperature applications with advanced temperature control.

- Flexible Atmospheres: Operates with Vacuum, Nitrogen, Nitrogen/Hydrogen, or Air, catering to various industrial needs.

- Multi-Chamber Options: Available in single, 2, 3, and 4 chamber configurations to fit multiple-stage processing requirements.

- Vacuum Level: 20 Microns, Gas Quench 1.5 Bar

- Temperature Range: 1000°F to 1975°F

- Ideal Industries: Automotive, Research and Development

Vacuum Pit Furnace: Custom and Standard Solutions for Diverse Industrial Needs

BEST FOR: Annealing, Hardening, Low Pressure Carburizing, Stress Relieving

- Customizable Designs: Offers both standard and engineered pit furnaces tailored to specific industrial requirements.

- Capacity and Size: Standard models handle up to 30,000 lbs., with dimensions ranging from 24 to 120 inches in diameter and 36 to 144 inches deep.

- Versatile Applications: Suitable for large workpieces and small parts in baskets.

- Advanced Features: Equipped with proprietary high-temperature fans for efficient heat distribution.

- Robust and Reliable: Built with heavy plate casings and steel plate lids to enhance durability and operational efficiency.

- Complete System Solutions: Includes companion equipment such as washers, temper furnaces, and quenches for a comprehensive heat treat line.

- Vacuum Level: 20 Microns, Gas Quench Pressure 2 bar

- Temperature Range: 1000°F to 2400°F

- Ideal Industries: Aerospace, Space Exploration, Aeronautical, Energy, and Oil

Carbottom Furnace

BEST FOR: Annealing, Hardening, Tempering, Stress Relieving, Heat Treating Large Castings and Forgings

- Advanced Loading Mechanism: Facilitates easy and seamless loading and unloading, perfect for heavy and large batch operations.

- High-Temperature Capability: Operates across a broad temperature range from 1000°F to 2400°F, accommodating various materials and processes.

- Atmosphere Control: Specializes in precise atmosphere conditions using options like RX® and DX® gases and various nitrogen mixtures for optimal material properties.

- Energy Efficiency: Incorporates recuperative technology, improving efficiency by up to 29%, reducing both operational costs and environmental impact.

- Durability and Longevity: Built with robust materials for durability, with many units proven to operate effectively for over fifty years.

- Vacuum Level: 50 microns, Gas Quench to 1 bar

- Temperature Range: 1000°F to 2400°F

- Ideal Industries: Aerospace, Automotive, Heavy Machinery, and Rail

cycle

cycle operation

operation hours per year

hours per year available space

available space operating temperature range

operating temperature range heat source

heat source