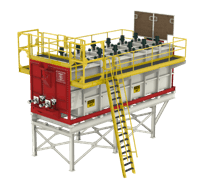

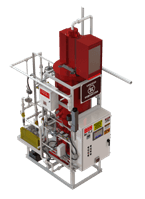

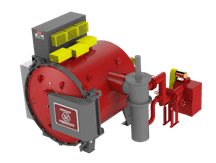

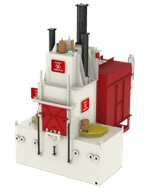

Surface offers a diverse line of industry-leading heat treat and thermal processing equipment built on decades of engineering expertise, industry knowledge, and technical support. We also offer custom-designed solutions. Talk to our team about your objectives today.

Furnace Selection Guide

Let’s find an innovative, efficient heat treat furnace solution for your thermal process needs. Our furnace selection guide is a great place to start.

Customer Service

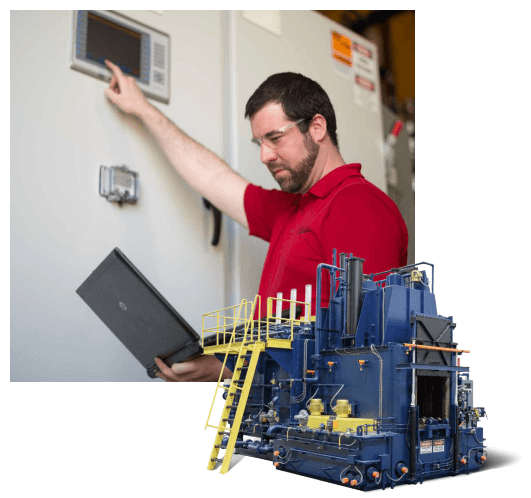

As your heat treatment furnace manufacturer, Surface has a top-notch customer service department, backed by decades of experience and historical documentation.

Learn MoreAftermarket Parts

Surface genuine replacements parts are backed by over 100 years of knowledge and experience that only an OEM can provide.

Learn MoreRebuild/Retrofit

Surface provides maintenance and upgrades by offering retrofit packages. Our technicians have the expertise to complete Machine Repair Overhaul (MRO) and furnace overhaul.

Learn More

Your partner for new ideas, technical expertise, and aftermarket service.

For over a century, Surface Combustion has been solving thermal processing challenges and helping our customers move forward. How can we help you?

Built to Perform

Engineering Expertise Makes the Difference

Surface continues to innovate and manufacture heat treat furnaces that deliver years and years of rugged dependability thanks to engineering expertise and design that leads the industry.

Over 675 Patents

Over 300,000 Installations

Over 75 Industry Recognized Trademarks

Installed in 50 Countries Worldwide

Surface Solutions

Insights & Expertise

SHOT Week Supplier Showcase

Optimize Energy Use With Surface Combustion

Surface Gas Heated Vacuum Technology Leads the Industry

Get to Know Heat Treatment!