Heat Treating for Forging

Billet Pre-Heating for Forging

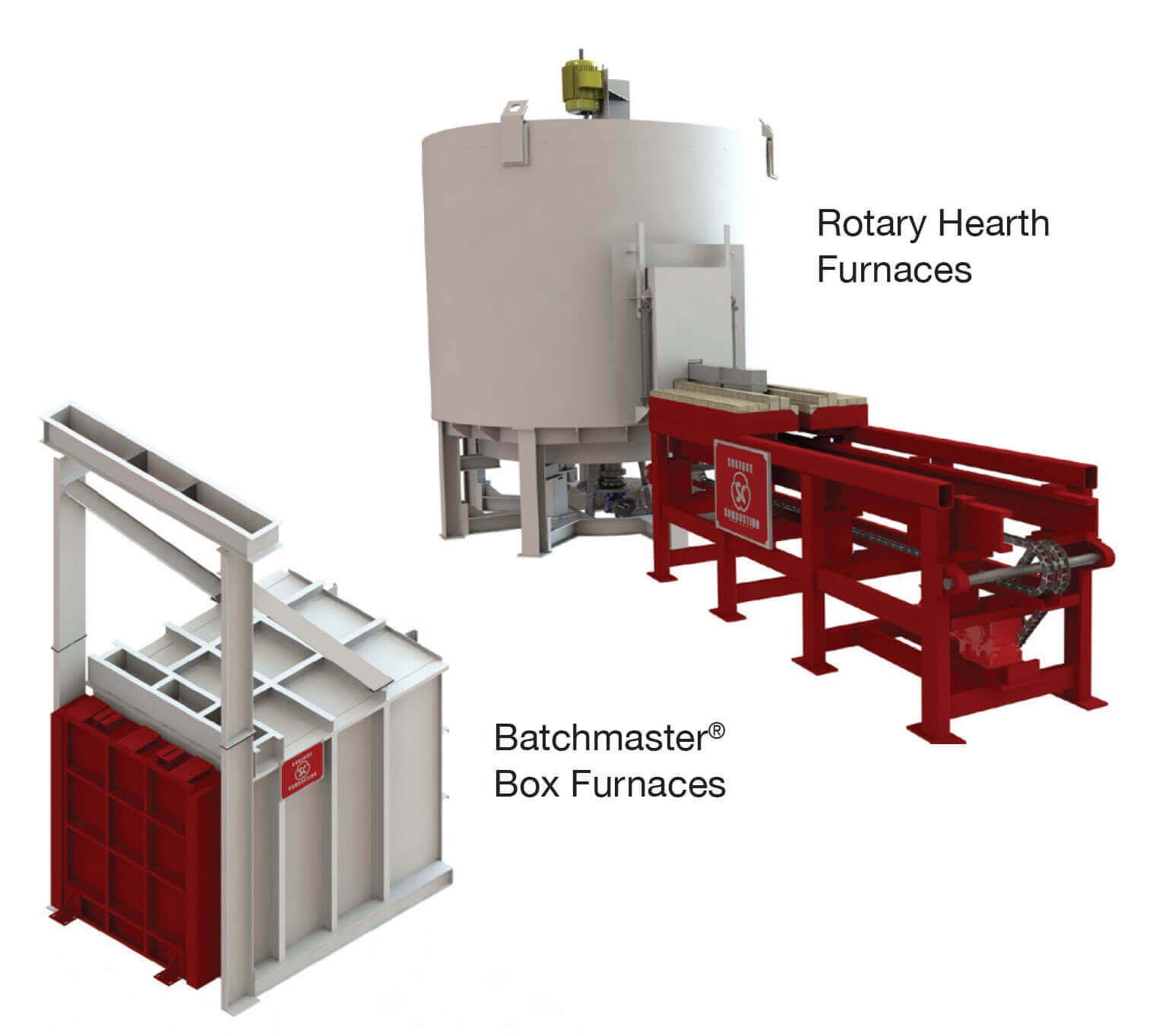

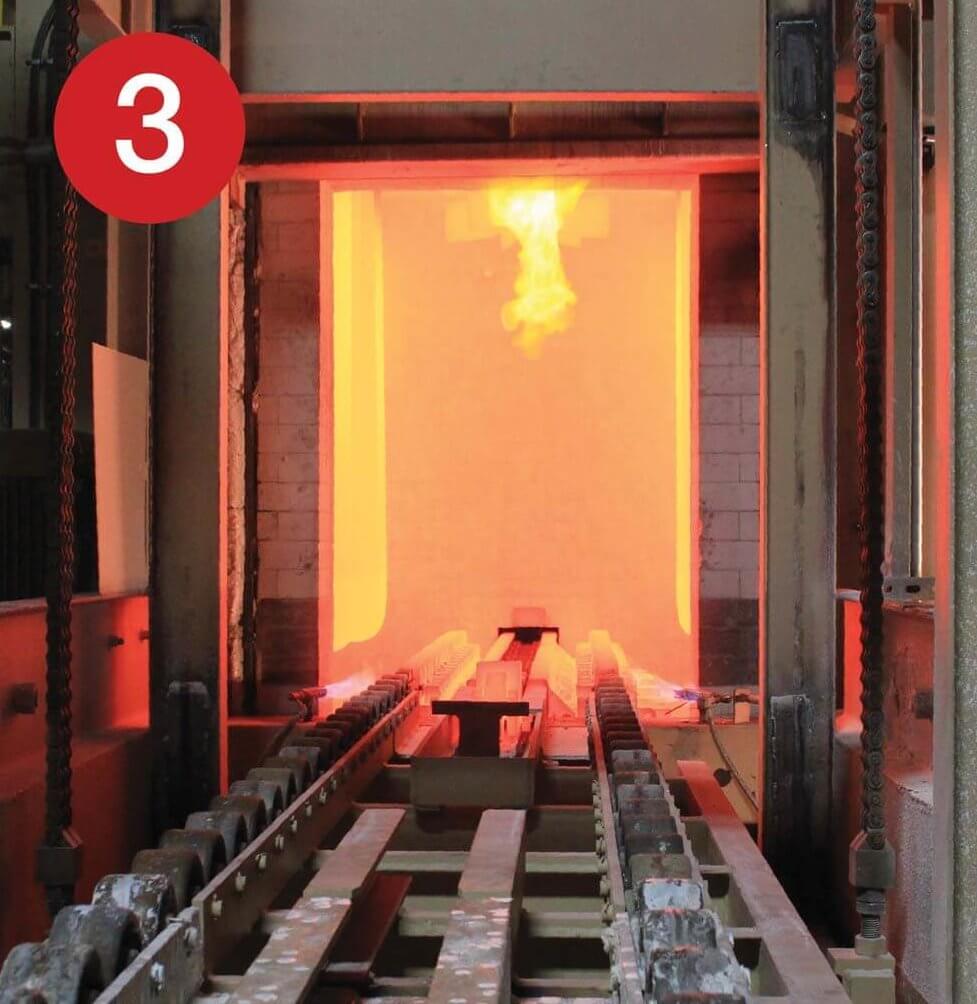

Rotary Hearth Furnaces offer a consistent, reliable, continuous option for pre-heating.

Key features include:

- Custom sizing 6′ to 80′ to meet your processing needs

- Maximum operating temperatures of 2250 °F

- Alloy or refractory hearth systems

- Ceramic fiber insulating systems

- Heating options include electric, direct gas fired (recuperative and regenerative), and radiant tube systems

- Robotic loading systems available

- Recirculating fans available

- Single- or multiple-door designs available

- Controlled atmosphere options include Nitrogen, RX® Endothermic, and DX® Exothermic

Batchmaster® Box Furnaces provide an ideal batch solution for your pre-heating needs.

Key features include:

- Standard internal widths and loading heights between 24″ and 72″ with standard loading weight up to 20,000 pounds. Custom sizes and weight capacities available upon request.

- Maximum operating temperatures of 2400 °F

- Ceramic fiber insulating systems

- Alloy or refractory hearth systems

- Heating options include electric, direct gas fired (recuperative and regenerative), and radiant tube systems

- Companion atmosphere generators and furnace loaders available

- Hydraulic lift cover, carbottom, and rotate systems optional

For over 100 years, Surface® Combustion has provided thermal processing equipment for the forging process.

We build the most rugged, reliable equipment for the pre-heating of billets, vacuum hardening and nitriding of forging dies, and heat treating of forgings. Surface also serves the various industries that benefit from forged components and has practical knowledge of the specifications that must be met. Surface equipment for forging matches the durable, dependable strength of your presses and hammers, and our aftermarket services ensure maximum uptime for your operation.

Heat Treatment for Forged Parts

Post-forge heat treatment varies from component to component depending on machining and tooling needs. Surface offers multiple batch and continuous solutions for normalizing, annealing, carburizing, carbonitriding, vacuum hardening, nitriding, and quench and temper.

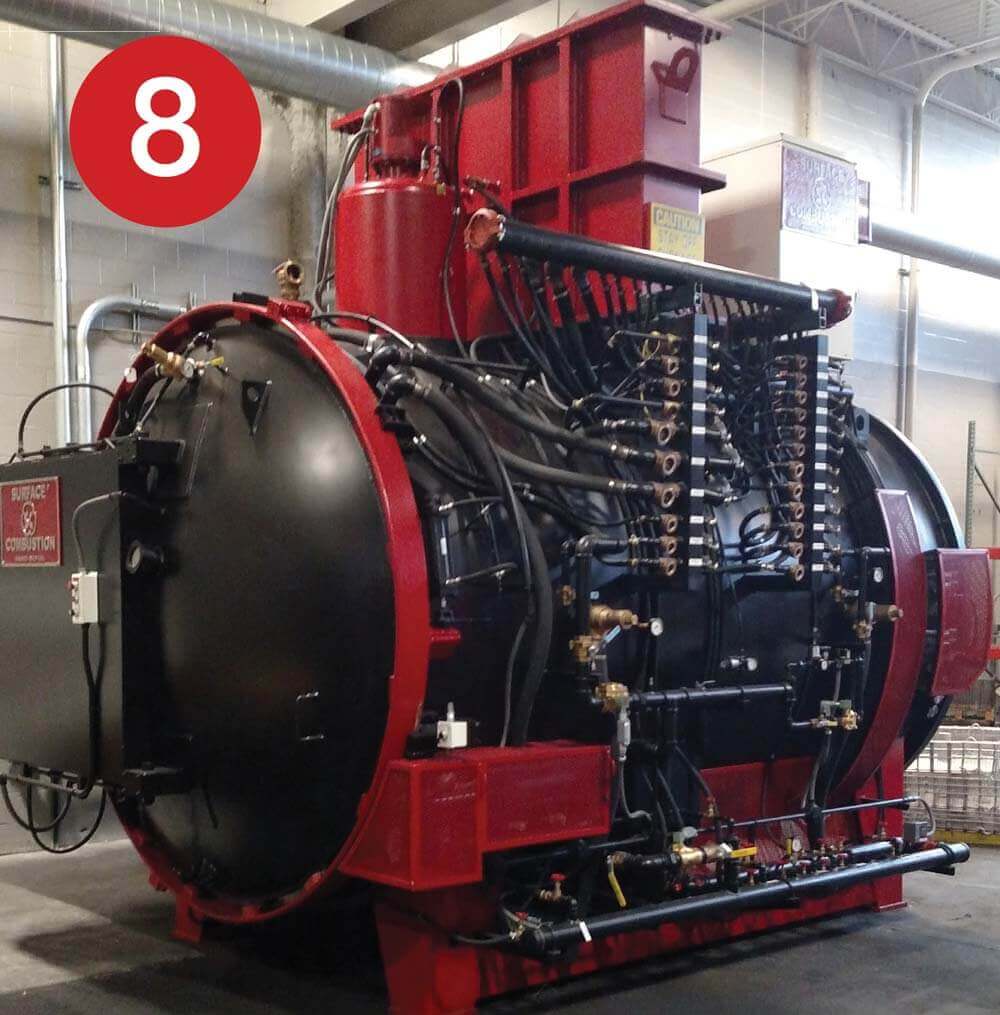

Heat Treating for Forging Dies

Die life is critical to any forging operation, and Surface provides heat treating solutions to help you extend the life of your dies and reduce tooling costs. Hot working dies, molds, and mandrels all experience strain and wear. In cold working, cold forge dies, wire and tube drawing dies, and stamping dies also benefit from proper heat treatment.

Available Furnace Solutions for Tool & Die Heat Treatment:

- PowerConvection® (PC) Vacuum Hardening Furnaces solutionize and harden tool steels with minimal distortion

- VacuDRAW® Vacuum Temper Furnaces temper or draw tool steels to increase toughness

- Gas Nitriding Furnaces and Ion (Plasma) Nitriding Furnaces add a wear resistant nitride layer to quenched and tempered die surfaces

- Box or Pit Type Furnaces pre-heat dies prior to hot work operation which reduces the risk of breakage and process scrap

Heat Treating for Forging Dies

Die life is critical to any forging operation, and Surface provides heat treating solutions to help you extend the life of your dies and reduce tooling costs. Hot working dies, molds, and mandrels all experience strain and wear. In cold working, cold forge dies, wire and tube drawing dies, and stamping dies also benefit from proper heat treatment.

Available Furnace Solutions for Tool & Die Heat Treatment:

- PowerConvection® (PC) Vacuum Hardening Furnaces solutionize and harden tool steels with minimal distortion

- VacuDRAW® Vacuum Temper Furnaces temper or draw tool steels to increase toughness

- Gas Nitriding Furnaces and Ion (Plasma) Nitriding Furnaces add a wear resistant nitride layer to quenched and tempered die surfaces

- Box or Pit Type Furnaces pre-heat dies prior to hot work operation which reduces the risk of breakage and process scrap

Ready to Get Started?

Please call us when you are ready to discuss a new furnace or maintain, upgrade or replace your furnace or any part of your furnace. At Surface, we look forward to helping you with any thermal processing needs.

Call Surface with the following information ready to initiate your furnace solution.

cycle

operation

hours per year

available space

operating temperature range

heat source

Give Us a Call