Treatment Options and Considerations

Part Specifications

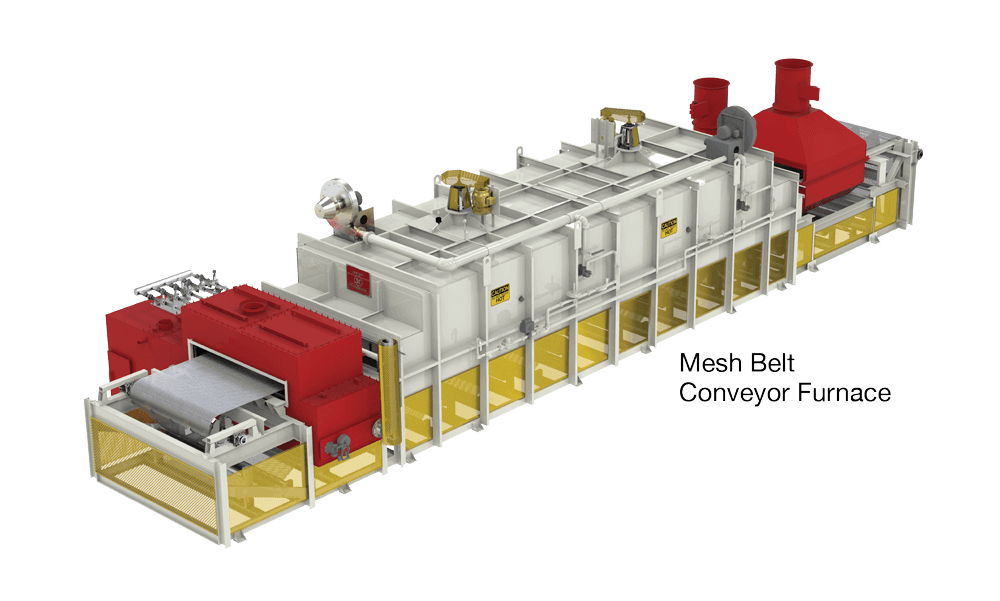

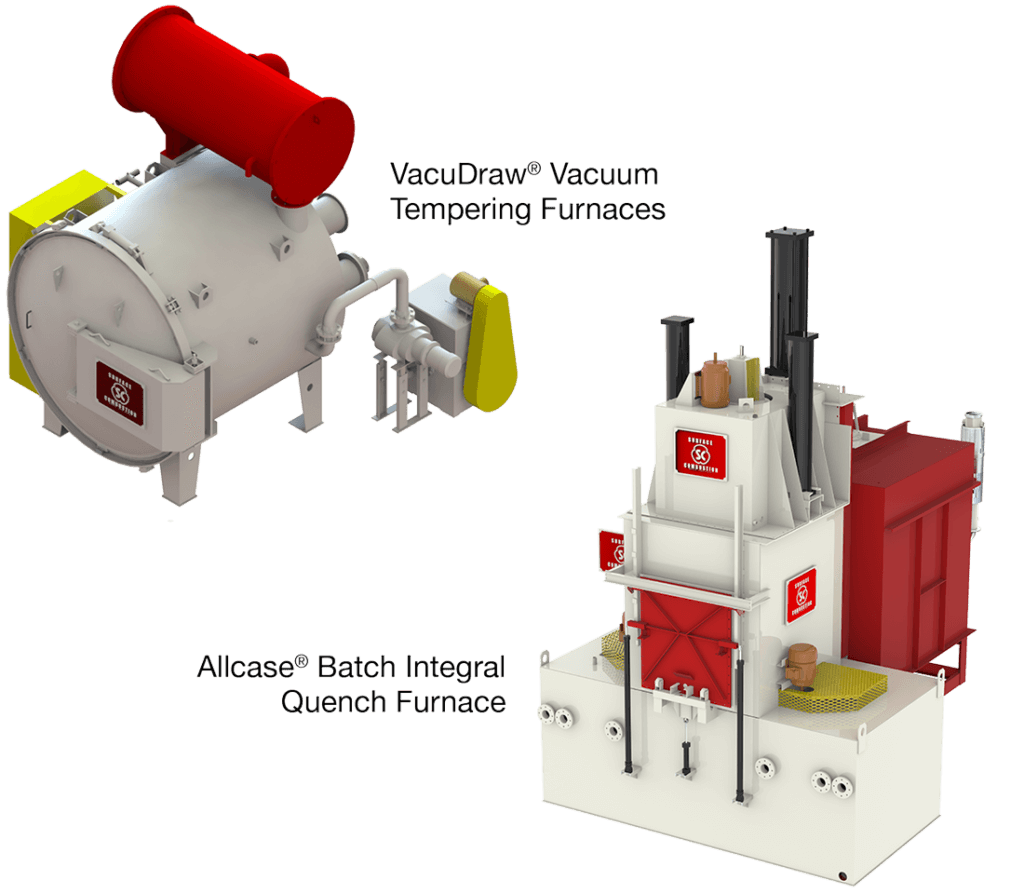

Surface furnace solutions for heat treating help ensure the performance

of gears to meet application needs and performance specifications.

- Low Distortion

- Tooth Hardness

- Case Depth Control

- Life Cycle Optimization

Process and Capacity Variables

Processes available for gear heat treatment are well established and controllable with atmosphere carburizing, while vacuum carburizing is modeled on a case by case since it is empirical. The technologies that have improved distortion are high pressure gas quenching, but better material grades are required, both add costs. Other advances are better insulation and heating technologies, improved process control sensors and better quench modeling/design. As such, the temperature uniformity, carburizing or nitriding potential uniformity and quenching are significantly better than in the past.

Comparing BIQ rated capacity today to continuous pusher furnaces shows batch loads are highly productive. Today it is advisable to invest in the flexibility of up to three BIQ furnaces before considering continuous pusher type furnaces.

Process Considerations

- Load mass and volume

- Part geometry

- Material alloy and hardenability

- Uniform case structure (root to pitch)

- Distortion control

Equipment Considerations

- Operating costs

- Maintenance costs

- Capacity

- Floor space requirements

- Infrastructure requirements