Belt Furnace

Surface® belt furnaces offer process uniformity,

reproducible product quality and value for your production line

Surface’s belt furnace product line allows for continuous processing of product types directly on mesh, cast link, flat wire or chain conveyors.

The belts are supported in the furnace by a series of rolls or skid supports. Furnaces can be provided in electric, direct fired and indirect gas fired configurations to meet specific processing requirements. For special processes, retorts can be incorporated into the design.

Belt Furnace Systems

Surface offers one of the industry’s largest selection of process types, furnace designs, and quenching systems.

Surface Solutions:

Surface belt furnaces are available with a variety of belt types for volume production of a wide range of sizes and shapes. The type of belt selected depends upon the shape, size, and weight of the parts that require heat treating. “Flat-surface” belt furnaces may have cast alloy links, slats or woven mesh belts. “Broken-surface” belt furnaces have troughs, flights or channels to support and convey work through the furnace.

Loads can be charged and discharged by hand, gravity, robotic or other automatic mechanisms. Continuous belts convey work directly through the furnace at a uniform speed with accurate time-cycle control. Work can be bulk loaded or precisely placed for product that requires oriented loading. Racks or baskets can be used for periodic short runs.

Loads can be charged and discharged by hand, gravity, robotic or other automatic mechanisms. Continuous belts convey work directly through the furnace at a uniform speed with accurate time-cycle control. Work can be bulk loaded or precisely placed for product that requires oriented loading. Racks or baskets can be used for periodic short runs.

The belt is supported by roller or skid supports depending on the operating temperature, belt type, loading and parts processed.

Application Requirements

- Thermal process solution with multiple stages

- Continuous production line

- Low energy consumption

- Large or small component solutions

- Predictable processing results

Available Products

- Mesh Belt Furnace

- Cast Belt Furnace

- Slat Conveyor Furnace

- Carrier Belt Furnace

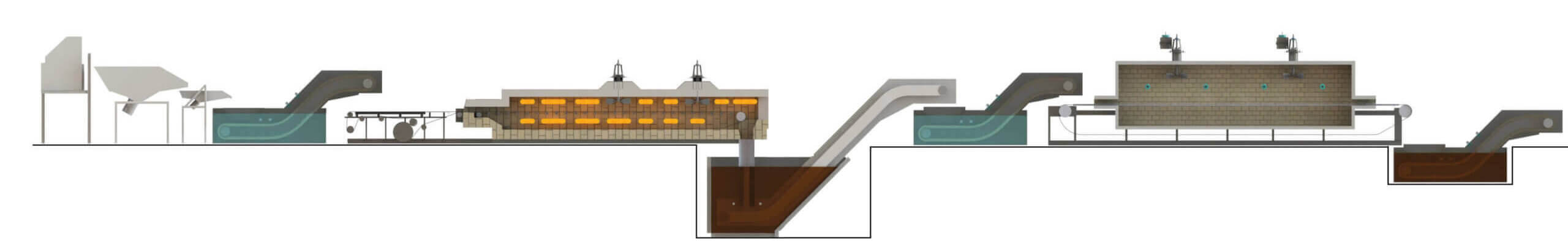

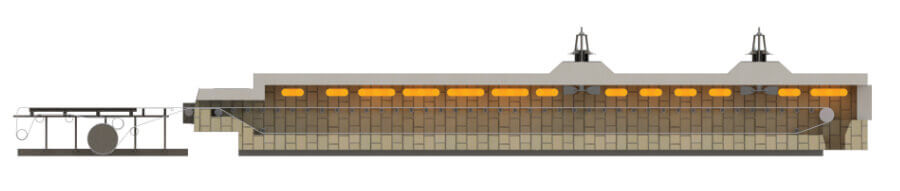

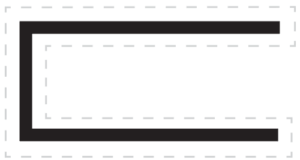

Example Configurations

Straight-Line

![]()

“U” Shape

Typical Furnace Line Equipment

Surface Processes:

The Belt Furnace will produce the right result for your load. Normalizing, hardening, stress relieving, carburizing, annealing, tempering, reheat for press quench, forging, austemper, carbonitriding, sintering, through hardening, normalizing, isothermal annealing, brazing are all processes capable in a belt furnace line.

Process atmosphere choices include: Nitrogen, endothermic (RX®), exothermic (DX®), air, nitrogen/ methanol, products of combustion, nitrogen/hydrogen or dissociated ammonia.

Quenchants include: Oil, polymer, caustic, high temperature salt.

Typically used to process: Steel, stainless steel, cast iron, aluminum, titanium, glass, powdered metal, copper and brass.

Ideal For:

Castings, forgings, aerospace components, bearings, gears, fasteners, stampings

Surface Results:

Flexible

One reason most consumers prefer the Surface Belt Furnace Systems is the flexibility. These systems can increase heat treating capabilities step by step and allow systematic planning for future heat treating demands. This is accomplished with a full line of available companion equipment that is offered to help build a complete, more profitable heat treating facility.

Rugged

Take one look at a Surface Belt Furnace Line and you’ll know it’s built to last. Surface chooses construction materials to maximize uptime and minimize maintenance. All of our belt furnaces, including our mesh belt furnaces, are built with sturdier steel, thicker insulation and heavier duty components than most of our competition. The high-quality alloy conveyance systems, robust heating systems and intelligently designed quenching systems are manufactured with the intent that they will work for long manufacturing campaigns.

Consistent and Long Lasting

Surface has over 100 years of history in the thermal processing business. Many Surface Belt Furnace Systems built over half a century ago are still in operation today. With your Surface Belt Furnace System, you can be assured that you will have consistent output, low operation costs, and many years of quality excellence. Surface furnaces are designed to be easy to maintain and are backed by one of the largest spare part inventories and genuine aftermarket, replacement parts in the industry.

Efficient

Surface Belt Furnace Systems are optimized to match your required production rate to yield the lowest cost of processing consistent, high quality work. Recuperated combustion systems are available for energy savings. Our control systems can monitor fuel consumption, atmosphere consumption, component production rate and overall furnace utilization to achieve maximum efficiency.

Made in the USA

Our Belt Furnaces are manufactured in the United States of America.

Furnace Line Equipment Configurations:

| Effective Belt Widths | Effective Belt Lengths | Production Rates (Pounds per Hour) | |

|---|---|---|---|

| Cast Belt Hardening | 24”-72” | 10’-60’ | 500-20,000 |

| Mesh Belt Hardening | 24”-66” | 8’-45’ | 250-7,500 |

| Belt Quenching Systems | 36”-84” | N/A | 250-7,500 |

| Mesh Belt Tempering | 36”-72” | 10’-50’ | 250-7,500 |

| Pre and Post Washers | 24”-60” | N/A | 250-7,500 |

| Soluble Oil Systems | 24”-60” | N/A | 250-7,500 |

Custom engineered sizes are available

Furnace Control System:

Surface offers a full line of process control systems from basic single loop controls to advanced Supervisory Control And Data Acquisition (SCADA) systems. The control systems are fully integrated with equipment safety hardware and PLC systems as required by each project.

The control system is the key to managing your furnace line for efficient production of quality product. These systems control temperature, conveyor speeds, atmosphere composition and product feed rate parameters.

The advanced SCADA systems offer additional functionality in:

- Recipe database

- Alarm database

- Historical trending of all key processes parameters

- Part lot tracking

- Real time part tracking through the entire process lines

- Historical retrieval of part lot processing parameters including temperature, atmosphere, process times, feed rates and any alarm conditions the occurred while processing

Ready to Get Started?

Please call us when you are ready to discuss a new furnace or maintain, upgrade or replace your furnace or any part of your furnace. At Surface, we look forward to helping you with any thermal processing needs.

Call Surface with the following information ready to initiate your furnace solution.

cycle

operation

hours per year

available space

operating temperature range

heat source

Give Us a Call