Our History

1904

1904

1915

1916

1916-1919

1920s

1930s

1940s

1950s

1960s-70s

1980s

1990s

2015

2021

2025

We know innovative industrial furnace design that delivers long-term dependability.

Surface Combustion continues to innovate and manufacture consistently reliable heat treat furnaces and thermal processing systems based on engineering expertise that leads the industry – ensuring that your treated metal products are always ahead of the rest.

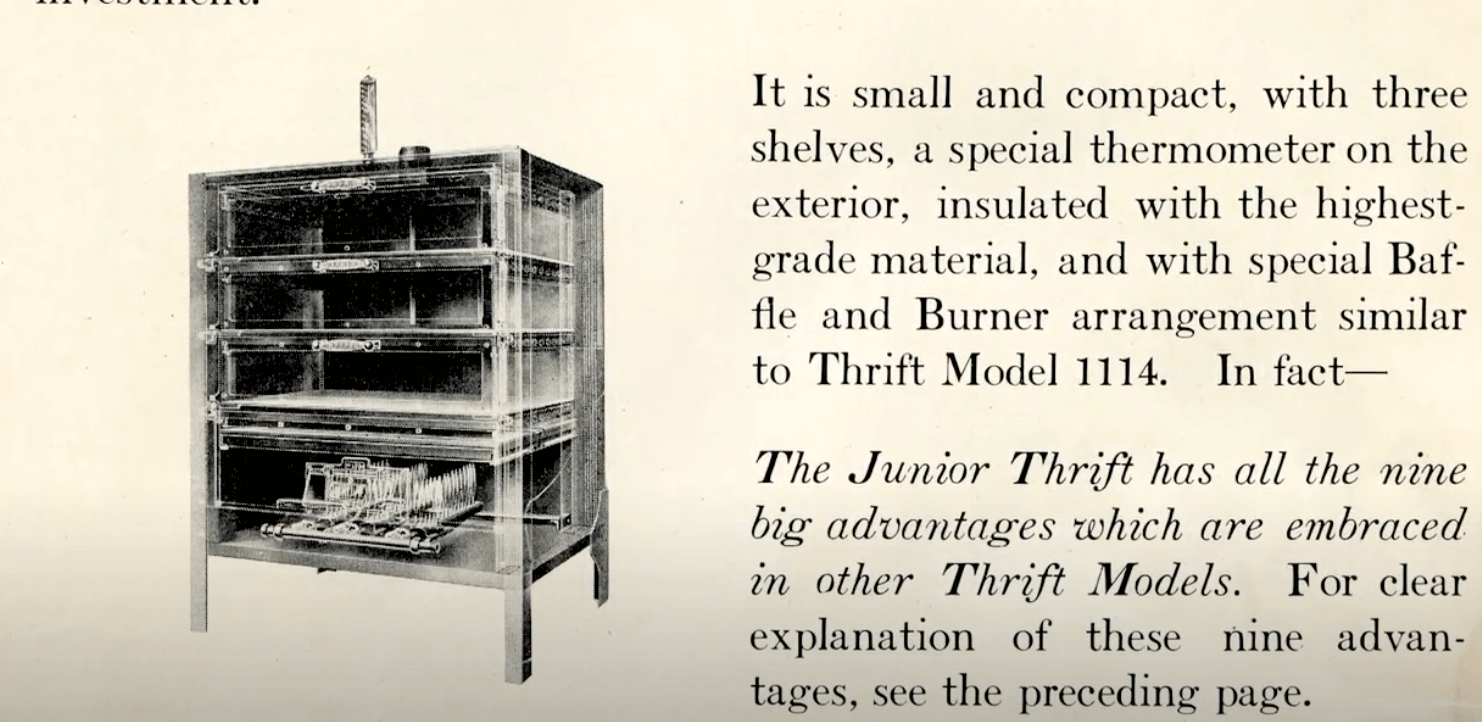

Today, our expanding product line includes vacuum heat treat furnaces, atmosphere heat treat furnaces, batch furnaces, and gas generators.

We know technologies that advance heat treat system performance.

To serve our industry with game-changing, state-of-the-art solutions, Surface continues to innovate and deliver heat treat furnace control systems. These offer remote, real-time monitoring and actionable data to ensure your thermal process is delivering consistent quality, optimal performance, and enhanced efficiency – every step of the way.

As an OEM of heat treat furnace systems, Surface Combustion is your best choice for integrating both process and mechanical controls. Going beyond basic controls, we offer systems for heat treat supervisory systems to control and manage recipes, parts, alarms, and production reports.

We know trusted heat treat furnace parts and retrofits keep your heat treat process moving.

At Surface Combustion, we also continue to innovate our approach to service and technical support of our industrial heat treat furnaces, providing quality replacement aftermarket parts and solutions backed by years of engineering leadership and manufacturing expertise.

Additionally, we can retrofit your existing furnace with quality Surface Combustion parts to improve efficiency, minimize repairs, and extend equipment life. Our technicians can install Surface retrofit resource parts during regularly scheduled maintenance shutdowns so your equipment downtime is as minimal as possible.

We know customer service backed with experience and expertise makes a difference.

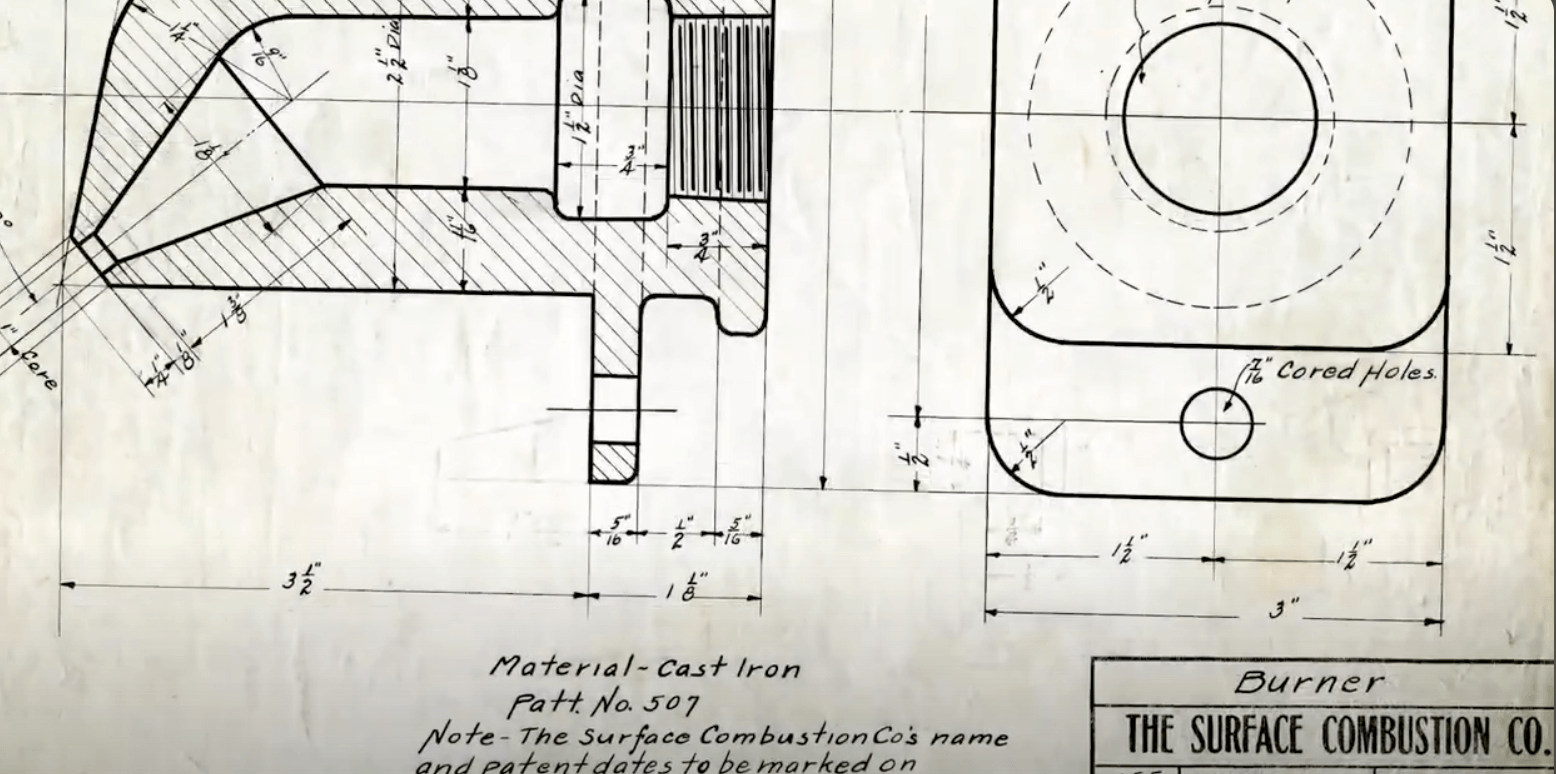

While driving industry advancements, we still know that the best customer service and support happens with personal connections and telephone conversations. If we can’t solve an issue remotely, we’ll dispatch an engineer to your site. Our service team is backed by extensive historical documentation, an in-house metallurgical test lab, and an extensive replacement parts inventory – all working together to ensure you have everything you need to keep running