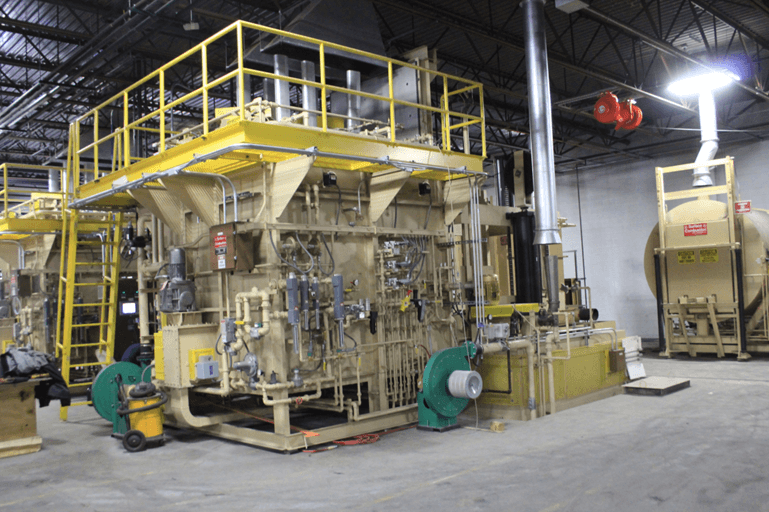

RTB™ Single-Chamber Atmosphere Box Furnace

RTB™ Single-Chamber Atmosphere Box Furnace

If you are looking for a single chamber atmosphere furnace, contact Surface Combustion today. Heat treaters worldwide know that Surface® furnaces provide greater value through an unmatched combination of reliability, repeatability and rugged performance. We will help you determine the optimum solution from our pre-engineered or custom designs for your process, product and material.

The RTBTM (Radiant Tube Box) Single-Chamber Atmosphere Box Furnace is a flexible, economical, pre-engineered design based on the hot zone of Surface’s legendary Allcase® Batch Integral Quench Furnace. Gas-fired radiant tubes or electric elements allow controlled atmosphere heat treatment with indirect heating – no internal alloy muffle assemblies are required. Easy to operate and maintain, the RTB can be customized to meet numerous process, product and material requirements and is available with the same standard sizes and hearth loadings as the Allcase.

Surface has long been known for its expertise in atmosphere processing. Whether the furnace uses RX® endothermic gas, DX® exothermic gas, nitrogen, nitrogen/methanol, nitrogen/hydrogen or any other process gas mixture, Surface has the experience and know how to provide an effective solution.

The RTB uses the latest technology in heating, energy efficiency and controls combined with Surface’s reputation for rugged furnace construction. The furnace casing is manufactured with gas-tight welded heavy steel plate supported by structural steel shapes. The insulation package is balanced to be energy efficient, allow rapid temperature changes and ease of maintenance. The RTB door is vertically lifted to allow front loading and uses Surface’s proprietary atmosphere tight door design. The furnace may be loaded by fork truck, charge car, or advanced automated charging systems. Multiple furnace hearth designs are available to support light or heavy workloads and enable automation.

You may choose either recuperated radiant tubes or electric elements for your RTB heating system. Radiant tube options include our patented TridentTM tube and vertically- or horizontally-mounted U-tube designs. For electric heating, we offer our proprietary ProlectricTM heating system. Both radiant tubes and Prolectric elements may be equipped with plunge cooling, which allows cooling of the load under atmosphere for processes such as isothermal annealing or equalizing for low distortion quenching.

Surface has spent decades of R&D (Research and Development) developing convective heating and atmosphere distribution systems. Our high-temperature VFTM fan units are critical to our success. Surface fans efficiently distribute the furnace atmosphere through our engineered wind flow patterns for uniform atmosphere and temperature distribution through the load.

An RTB can be designed to stand alone or be part of a new or existing furnace line. Surface provides a wide range of companion equipment, advanced controls and support services for single source responsibility. This allows you peace of mind that your installation will run smoothly, and your equipment will be taken care of for the long term.

Based on the industry-leading Allcase hot zone

Maximum operating temperatures up to 1950°F

Multiple gas fired heating systems available including vertical and horizontal radiant tube configurations.

Electric heating systems available including Proletric® style and canned element style

Roller rail or skid hearth systems

Oil, water, polymer, high temperature salt, and brine quench systems available

Atmosphere Cool Chambers (Top Cool) available

Numerous automation and networking controls available

Allcase® family also includes RTB (Radiant Tube Box) and ACT (Radiant Tube Box Furnace with Atmosphere Top Cool)

Proprietary VF™ fan extends fan life by minimizing vibration and gives uniform atmosphere distribution

Annealing

Austempering

Carbon Restoration

Carbonitriding

Carburizing

Forging

Hardening

Malleablizing

Marquenching

Normalizing

Pre-Heating

Solutionizing

Spheroidizing

Stress Relieving

Partial processes list shown. Looking for something specfic, contact us.

Aerospace

Agricultural

Aluminum Processing

Automotive

Bearings

Commercial Heat Treating

Energy Efficiency Considerations

Fasteners

Gears

Off Road/Mining/Excavation

Oil & Gas

Wind Power

Partial industries list shown. Looking for something specfic, contact us.

Aerospace Components

Bearings

Billet

Cast and Ductile Iron

Casting

Chain

Copper

Cutlery

Extrusion Screws

Fasteners

Forgings

Gears

Hand Tools

Pinions

Powdered Metal

Rock Bits

Rod Coil

Shafts

Springs

Stainless Steels

Stampings

Steel

Studs

Tool Steels

Partial material and component list shown. Looking for something specfic, contact us.

Partial companion equipment list shown. Looking for something specfic, contact us.

Surface® is Your Source

CONTACT US TODAY, and let us show you the Value of Surface™

Ready to Get Started?

Please call us when you are ready to discuss a new furnace or maintain, upgrade or replace your furnace or any part of your furnace. At Surface, we look forward to helping you with any thermal processing needs.

Call Surface with the following information ready to initiate your furnace solution.

cycle

operation

hours per year

available space

operating temperature range

heat source

Give Us a Call