Why Heat Treaters Choose DX® Generators

Manufacturing engineers and plant managers select DX® generators for compelling operational advantages:

Many customers want the flexibility of higher combustibles in the range of 10% CO (Carbon Monoxide) and Hydrogen (rich exothermic) AND lower combustibles in the range of 4% CO and Hydrogen (lean exothermic). Surface Combustion can offer both capabilities in the same generator with a simple change of the burner air/gas ratio. The standard generator is manually adjusted to produce lean or rich atmospheres by changing the air-to-gas ratio. Multiple fuels may be used to create DX gas.

DX generators are designed and intended to run and run with minimal downtime. Controls technology at the generator are dewpoint sensor or oxygen probe based. Safety aids in accordance with NFPA 86 standards. Start-up assistance and operator training provided.

Today’s exogas generator involves an insulated firing chamber with a top mounted burner firing downward into a water sump of sorts located at the bottom of the generator to quench the flame. This quenched gas is at approximately 100 degree dewpoint at this initial step which is too damp for most applications. First stage drying happens when the DX gas is passed through an integral refrigerant based direct expansion chiller which drives the gas dewpoint down further into the range of 35 to 40 degrees. Several applications in electric motor application require a third stage of drying using desiccant technology to drive the moisture down further to approximately 20 degrees. All of this is necessary for properly balancing the CO/CO2 and H2/H20 ratios in the presence of steels of different carbon potentials.

Surface® Combustion annular cooled DX® Gas Generators provide efficient, low cost, and reliable production of exothermic gas. This unique cooling system minimizes required floor space and eliminates the need for a hot crossover pipe between the combustion chamber and the heat exchanger. Compact, annular cooled design with stainless steel casing and combustion barrel.

Shop tested prior to shipment. Modifications can be made to further refine product gas to create NX® and HNX® gas. Optional automatic turndown systems available.

Learn more about the full capabilities of our DX® Exothermic Gas Generators

Metallurgical Excellence Through Generated Atmospheres in Heat Treatment

DX® generators excel in diverse thermal processing applications

- Annealing

- Blanketing

- Bluing

- Brazing

- Bright Annealing

- Ferritic Nitrocarburizing (FNC)

- Normalizing

- Purging

- Sintering

- Tempering

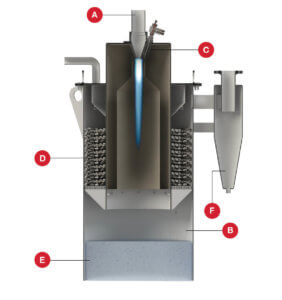

Main Generator Construction

A. Combustion System

- Air, supplied by a blower, and fuel each have direct reading flowmeter

- Air and fuel mixed in standard Surface Combustion mixer with an air-flow based constant proportioning system enabling 2:1 turndown

- Air-fuel ratio manually set by variable orifice located in fuel gas line

- Standard Surface Combustion premix tunnel burner system with integrated pilot and dual flame sensors produces product gas

- Natural gas and many other fuels may be used to make DX gas

B. Generator Casing

- Stainless steel construction to minimize corrosion

- Contains combustion barrel, annular cooler, and recirculation condensate sump

C. Combustion Barrel

- Stainless steel construction to minimize outer barrel corrosion and lined with castable refractory to maximize inner barrel temperature

- Integral cover plate bolts to generator casing to easily remove barrel for maintenance

D. Annular Cooler

- Formed by the space between the outside of the combustion barrel and the inside of the generator casing

- Cooling water moves counterflow to product gas

- Filled with high surface area stainless steel rings to maximize contact between water and gas

E. Recirculation Condensate Sump

- Located at the bottom of the generator casing

- Cools product gas leaving combustion barrel and turns it into annual cooler

- Collects condensate from product gas as it cools then recirculates it into the annular cooler

- Proximity level activated solenoid valve automatically controls sump water level

F. Cyclone Separator

- Product gas spins and cools within cyclone while water condenses out from it

- Condensate transferred to recirculation condensate sump

DX gas leaves cyclone with a dewpoint of approximately 100°F

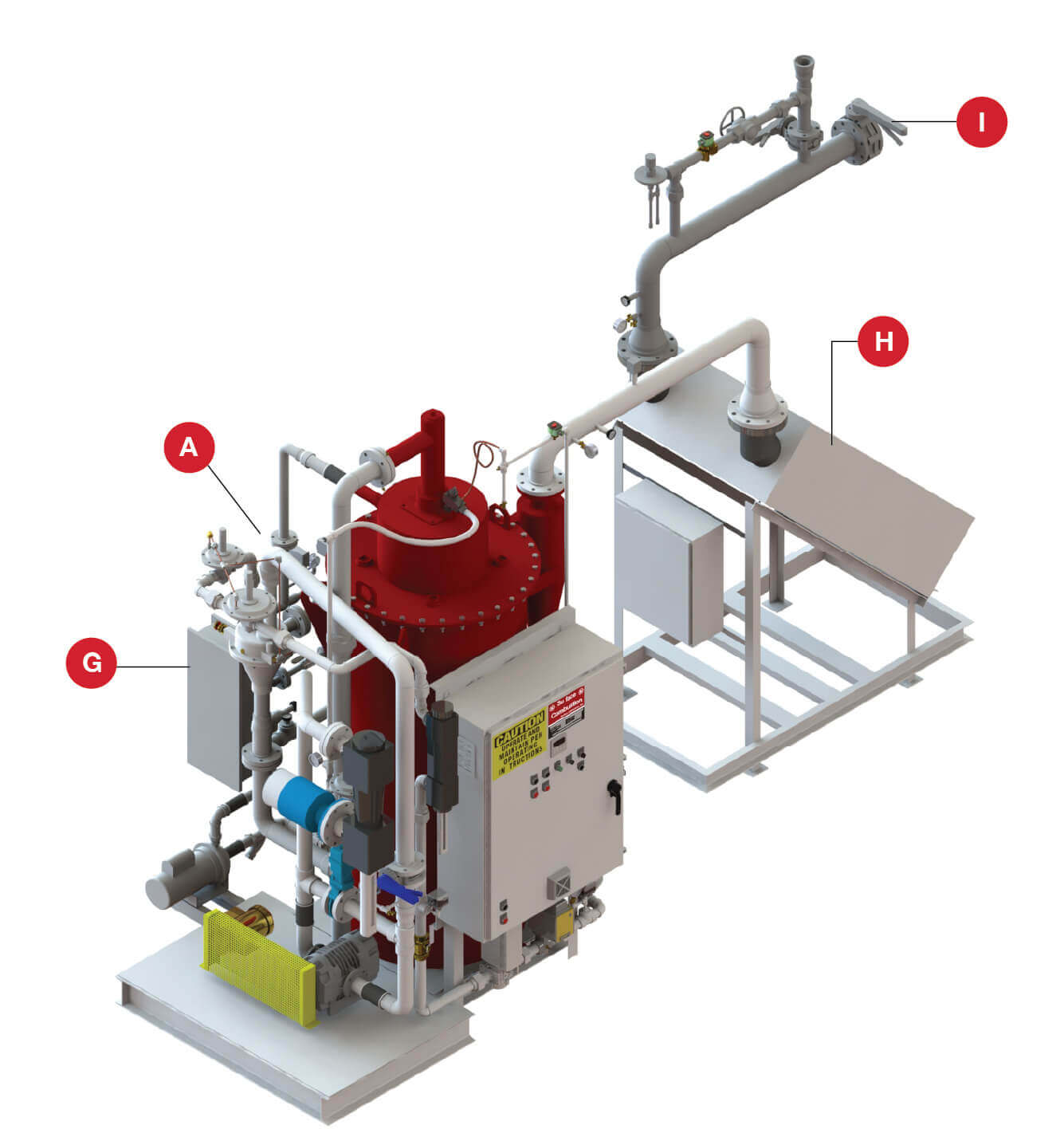

G. Recirculating Condensate Cooling System (Optional)

- Water in sump cooled by water- or air-cooled heat exchanger

- Lowers product gas oxygen concentration to approximately 75 ppm

H. DX Chiller System (Optional)

- Product gas is dehydrated to approximately 40°F dewpoint by water- or air-cooled chiller

I. Process Gas Delivery

- Automatic vent relief regulator set at 14″ w.c. (3.5 kPa)

- Can be tied to optional automatic turndown system to reduce DX gas supply based on demand

Technical Specifications

Generator Capacities

- DX-4M: 4,000 cfh maximum (2,000 cfh minimum)

- DX-6M: 6,000 cfh maximum (3,000 cfh minimum)

- DX-8M: 8,000 cfh maximum (4,000 cfh minimum)

- DX-10M: 10,000 cfh maximum (5,000 cfh minimum)

- DX-15M: 15,000 cfh maximum (7,500 cfh minimum)

- DX-20M: 20,000 cfh maximum (10,000 cfh minimum)

- DX-25M: 25,000 cfh maximum (12,500 cfh minimum)

Standard Features

- Wide range of product gas compositions by varying air/gas ratio

- 2:1 turndown

- Multiple fuels may be used to create DX gas

- Compact, annular cooled design

- Stainless steel casing and combustion barrel

- Safety aids in accordance with NFPA 86 standards

- Start-up assistance and operator training

Optional Systems

- Water- or air-cooled recirculating condensate system

- Water- or air-cooled DX chiller system

- Additional refining equipment to reduce dewpoint or create NX® or HNX® gas

- Automatic turndown

Applications and Processes

Heat Treating Processes

- Annealing

- Bluing

- Brazing

- Bright Annealing

- Ferritic Nitrocarburizing (FNC)

- Normalizing

- Purging

- Sintering

- Stress Relieving

- Temper

Compatible Furnace Systems

- Batch and continuous furnaces

Frequently Asked Questions About DX® Exothermic Gas Generators

What is an exothermic gas generator?

An exothermic gas generator produces protective atmospheres by burning a controlled mixture of air and fuel gas in an insulated firing chamber with a top mounted burner firing downward into a water sump to quench the flame. Surface® Combustion named this exothermic gas with the tradename of DX® gas.

How does the DX® generator differ from endothermic generators?

DX® exothermic generators involve an insulated firing chamber with combustion, while endothermic generators react fuel and air over a catalyst with heat input. The materials do not provide detailed technical comparisons between the two types.

What size DX® generator do I need for my operation?

DX® generators range from 4,000 CFH to 25,000 CFH with specific models: DX-4M (4,000 cfh maximum, 2,000 cfh minimum), DX-6M (6,000 cfh maximum, 3,000 cfh minimum), DX-8M (8,000 cfh maximum, 4,000 cfh minimum), DX-10M (10,000 cfh maximum, 5,000 cfh minimum), DX-15M (15,000 cfh maximum, 7,500 cfh minimum), DX-20M (20,000 cfh maximum, 10,000 cfh minimum), and DX-25M (25,000 cfh maximum, 12,500 cfh minimum). All units feature 2:1 turndown capability.

What is the typical composition of DX® gas?

The generator provides a wide range of product gas compositions by varying air/gas ratio. Rich exothermic contains approximately 10% CO and 10% hydrogen, while lean exothermic contains approximately 4% CO and 4% hydrogen.

What fuel types can be used in DX® generators?

Natural gas and many other fuels may be used to make DX gas. Multiple fuels may be used to create DX gas. Air and fuel each have direct reading flowmeter with air-fuel ratio manually set by variable orifice located in fuel gas line.

What heat treating processes can use DX® generated atmospheres?

DX® generators support annealing, blanketing, bluing, brazing, bright annealing, ferritic nitrocarburizing (FNC), normalizing, purging, sintering, stress relieving, and tempering.

Can I produce both rich and lean exothermic atmospheres with the same generator?

Yes, many customers want the flexibility of higher combustibles in the range of 10% CO and Hydrogen (rich exothermic) AND lower combustibles in the range of 4% CO and Hydrogen (lean exothermic). Surface Combustion can offer both capabilities in the same generator with a simple change of the burner air/gas ratio.

Why does the product gas require multiple stages of drying?

The quenched gas is at approximately 100 degree dewpoint at the initial step which is too damp for most applications. First stage drying happens when the DX gas is passed through an integral refrigerant based direct expansion chiller which drives the gas dewpoint down further into the range of 35 to 40 degrees. Several applications in electric motor application require a third stage of drying using desiccant technology to drive the moisture down further to approximately 20 degrees.

How does the cyclone separator improve gas quality?

Product gas spins and cools within cyclone while water condenses out from it. Condensate is transferred to recirculation condensate sump. DX gas leaves cyclone with a dewpoint of approximately 100°F.

How does the annular cooling system work?

The annular cooler is formed by the space between the outside of the combustion barrel and the inside of the generator casing. Cooling water moves counterflow to product gas and is filled with high surface area stainless steel rings to maximize contact between water and gas. This unique cooling system minimizes required floor space and eliminates the need for a hot crossover pipe between the combustion chamber and the heat exchanger.

Can DX® generators be automated for demand-based operation?

Yes, optional automatic turndown systems are available and can be tied to the automatic vent relief regulator to reduce DX gas supply based on demand.

What safety features are included with DX® generators? Standard safety features include integrated pilot and dual flame sensors in the premix tunnel burner system, and safety aids in accordance with NFPA 86 standards.

What is the difference between water-cooled and air-cooled options?

Water- or air-cooled recirculating condensate system and water- or air-cooled DX chiller system are available as optional systems.

How does the recirculating condensate system improve performance?

Water in sump can be cooled by water- or air-cooled heat exchanger, which lowers product gas oxygen concentration to approximately 75 ppm.

What maintenance is required for DX® generators?

The combustion barrel has an integral cover plate that bolts to generator casing to easily remove barrel for maintenance. The stainless steel construction minimizes corrosion.

How does the stainless steel construction benefit long-term operation?

Stainless steel construction of the casing and combustion barrel minimizes corrosion. The combustion barrel is lined with castable refractory to maximize inner barrel temperature.

Can DX® generators operate continuously for extended periods?

DX generators are designed and intended to run and run with minimal downtime. Controls technology at the generator are dewpoint sensor or oxygen probe based.

What technical support is provided with DX® generators?

Surface Combustion provides start-up assistance and operator training. DX generators are shop tested prior to shipment.

What industries typically use DX® exothermic gas generators?

DX® generators are used widely in the pipe, tube, wire and motor industries, as well as many annealing, normalizing and bluing applications.

Can DX® gas be further refined for specialized applications?

Yes, modifications can be made to further refine product gas to create NX® and HNX® gas. Additional refining equipment is available to reduce dewpoint or create NX® or HNX® gas.

Stainless steel construction

Can create rich or lean atmosphere

Water cooled recirculating condensate cooling system

Optional water cooled packaged chiller, provided where low process gas dew point is critical

Shop tested prior to shipment

Modifications can be made to further refine product gas to create NX® and HNX® gas

Annealing

Bluing

Brazing

Bright Annealing

Ferritic Nitrocarburizing (FNC)

Normalizing

Purging

Sintering

Stress Relieving

Temper

Partial processes list shown. Looking for something specfic, contact us.

Aerospace

Agricultural

Automotive

Chemical & Petroleum

Electric Motors

Food Processing

Off Road/Mining/Excavation

Oil & Gas

Partial industries list shown. Looking for something specfic, contact us.

Aluminum

Brass

Chemical and Petroleum

Copper

Food Processing

Motor Laminations

Silicon Steel

Stainless Steels

Steel

Tube

Partial material and component list shown. Looking for something specfic, contact us.

Chiller

Partial companion equipment list shown. Looking for something specfic, contact us.

Surface® is Your Source

CONTACT US TODAY, and let us show you the Value of Surface™