DX® Exothermic Gas Generators

DX® Exothermic Gas Generators

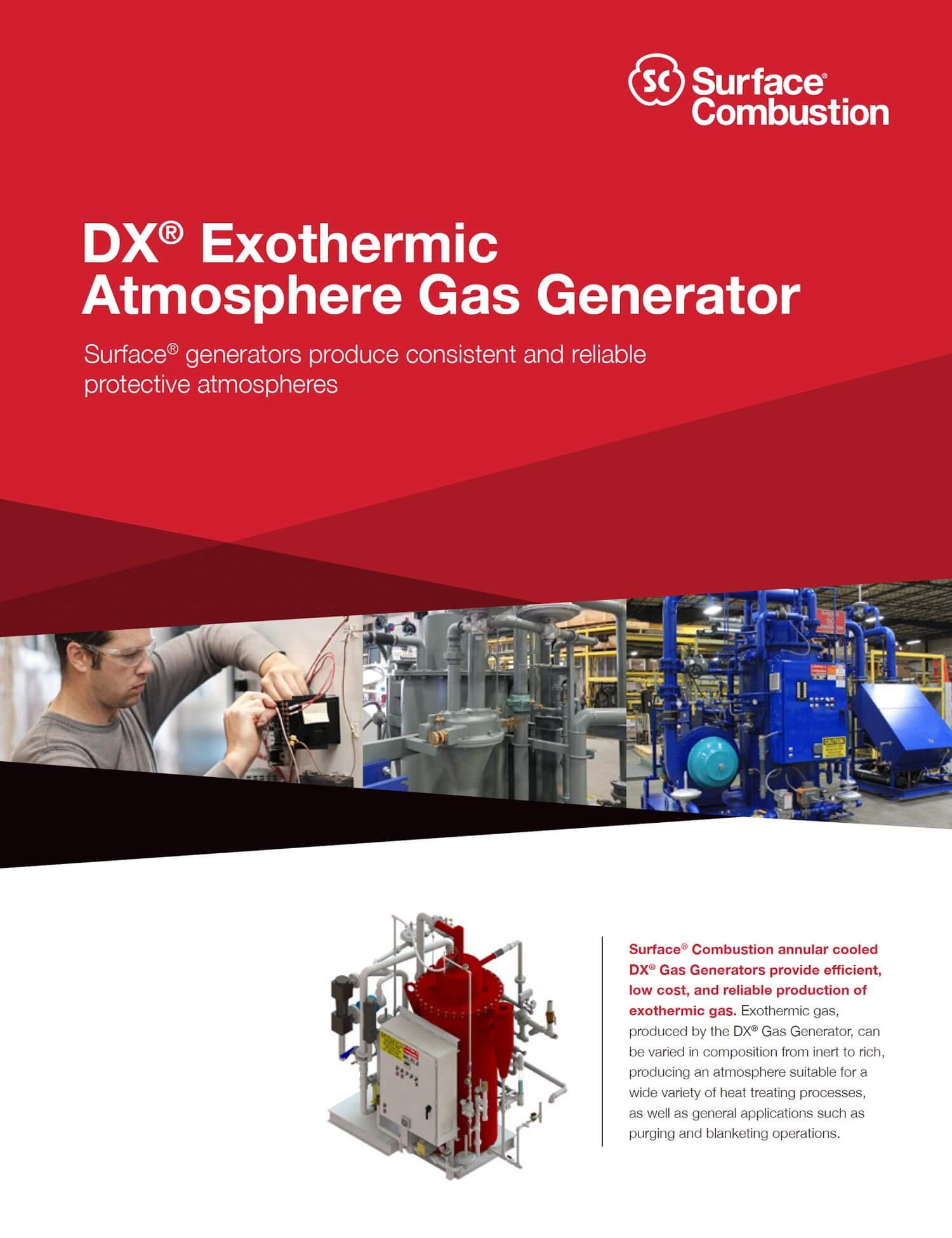

When you look to purchase anything in life, you always feel more comfortable when you go to the experts. As a leading heat treat furnace manufacturer, Surface® Combustion has a vast installed base of exothermic (exogas) atmosphere furnace gas generators and while the industrial segment of exothermic atmosphere furnace gas applications is far less than endothermic applications, we maintain our position as a generated gas expert by offering a world of experience and the latest technologies available!

Surface® Combustion leads the way with a versatile exothermic design that is used in many annealing, normalizing and bluing applications used widely in the pipe, tube, wire and motor industries. Many customers want the flexibility of higher combustibles in the range of 10% CO (Carbon Monoxide) and Hydrogen (rich exothermic) AND lower combustibles in the range of 4% CO and Hydrogen (lean exothermic). Surface Combustion can offer both capabilities in the same generator with a simple change of the burner air/gas ratio. To complete the exogas production process, this gas is further chilled to lower dewpoints before it is suitable to be introduced into various styles of batch and continuous furnaces.

Surface named this miracle exothermic gas with a tradename of DX® gas.

Today’s exogas generator involves an insulated firing chamber with a top mounted burner firing downward into a water sump of sorts located at the bottom of the generator to quench the flame. This quenched gas is at approximately 100 degree dewpoint at this initial step which is too damp for most applications. First stage drying happens when the DX gas is passed through an integral refrigerant based direct expansion chiller which drives the gas dewpoint down further into the range of 35 to 40 degrees. The majority of annealing and normalizing processes can use the DX gas at after this first chilling stage. Several applications in electric motor application require a third stage of drying using desiccant technology to drive the moisture down further to approximately 20 degrees. All of this is necessary for properly balancing the CO/CO2 and H2/H20 ratios in the presence of steels of different carbon potentials.

Depending on the physical size of the units, various sizes can produce a minimum of 2000 cfh (cubic feet per hour) up to a maximum of 30,000 cfh. Typical DX generators have 2 to 1 turn down capabilities to allow for reducing flow when furnaces are taken off line or when furnace vestibules need to be purged with higher flows before returning to lower flows. For many continuous applications where possible large swings in gas flow requirements might be possible, we offer the capabilities of multiple units to operate in tandem to allow for 4 to 1 capability as well without sacrificing any quality of gas composition whatsoever.

DX generators are designed and intended to run and run with minimal downtime. Controls technology at the generator are dewpoint sensor or oxygen probe based. It is possible that the gas can be leaned out even further or enriched. Indeed some wire and tube applications of medium carbon steels require an RX® Generator and a DX® Generator precisely balanced in various zones of a continuous furnace.

Learn more about the full capabilities of our DX® Exothermic Gas Generators

Stainless steel construction

Can create rich or lean atmosphere

Water cooled recirculating condensate cooling system

Optional water cooled packaged chiller, provided where low process gas dew point is critical

Shop tested prior to shipment

Modifications can be made to further refine product gas to create NX® and HNX® gas

Annealing

Bluing

Brazing

Bright Annealing

Ferritic Nitrocarburizing (FNC)

Normalizing

Purging

Sintering

Stress Relieving

Temper

Partial processes list shown. Looking for something specfic, contact us.

Aerospace

Agricultural

Automotive

Chemical & Petroleum

Electric Motors

Food Processing

Off Road/Mining/Excavation

Oil & Gas

Partial industries list shown. Looking for something specfic, contact us.

Aluminum

Brass

Chemical and Petroleum

Copper

Food Processing

Motor Laminations

Silicon Steel

Stainless Steels

Steel

Tube

Partial material and component list shown. Looking for something specfic, contact us.

Chiller

Partial companion equipment list shown. Looking for something specfic, contact us.

Surface® is Your Source

CONTACT US TODAY, and let us show you the Value of Surface™

Ready to Get Started?

Please call us when you are ready to discuss a new furnace or maintain, upgrade or replace your furnace or any part of your furnace. At Surface, we look forward to helping you with any thermal processing needs.

Call Surface with the following information ready to initiate your furnace solution.

cycle

operation

hours per year

available space

operating temperature range

heat source

Give Us a Call