Belt Furnaces

Belt Furnaces

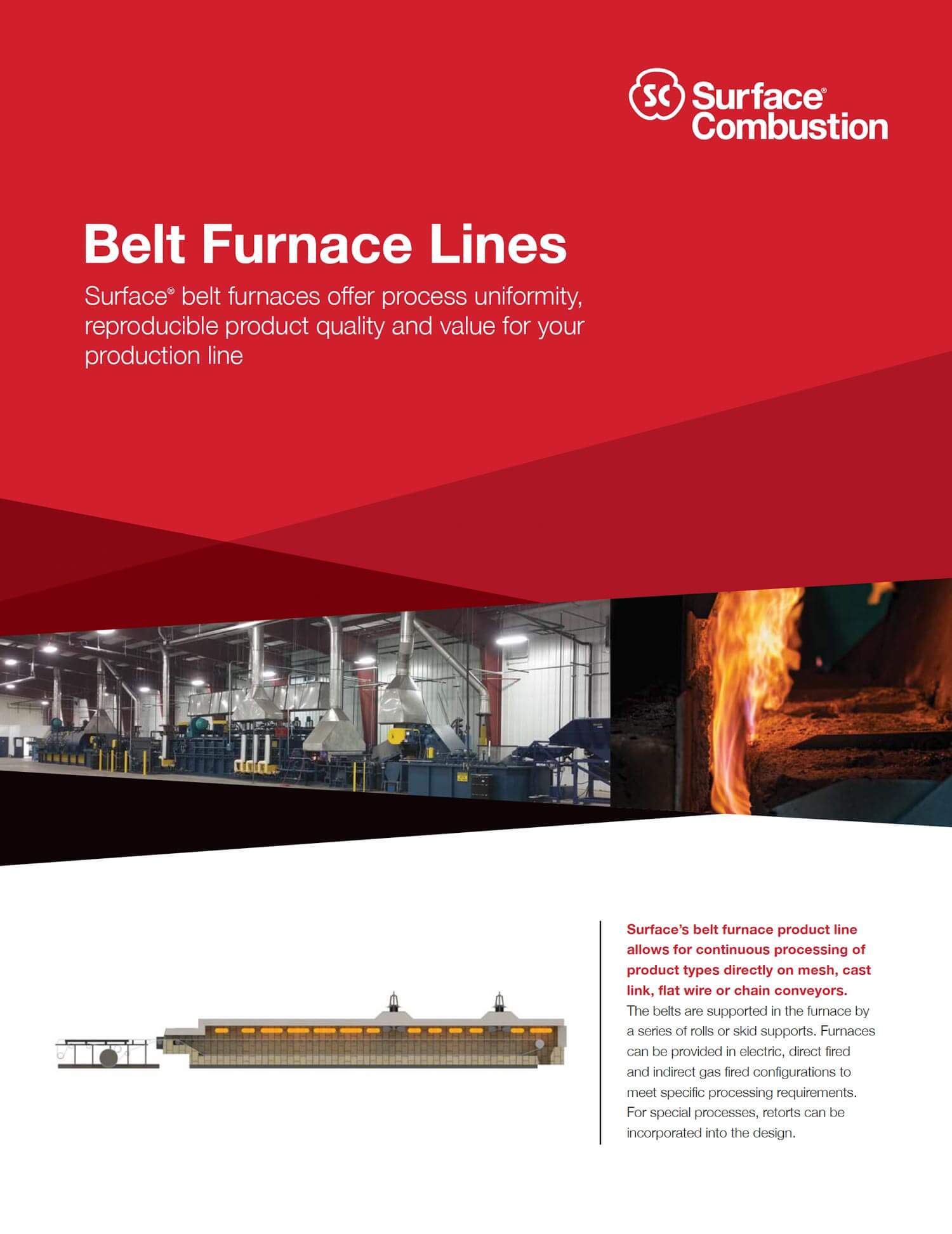

When you look to purchase anything in life, you always feel more comfortable when you go to the experts. As a leading heat treat furnace manufacturer, Surface Combustion has more than 100 years of experience with thermal systems. One style of furnace used for fasteners, stampings, forgings or other components is a belt type furnaces. These can utilize mesh, cast link, or slat conveyor belts. Within this belt furnace style, individual or bulk loaded parts are placed onto the belt which is then conveyed through the furnace. The belt serves as the moving transport, and it operates in a continuous fashion. Post processes include quenching and washing or after tempering it can be soluble oil or other rust preventative treatments.

Surface® Combustion’s belt furnaces start with an insulated hot zone which typically includes a bricked floor and walls and a fiber lined roof. The heating source can be direct or indirect gas fired or electric elements. For those products requiring an internal atmosphere, only indirect gas firing and electric heating may be used. Endothermic (RX®) gas forms the base gas necessary for through hardening or carburizing. The belt style is either a woven mesh belt of a high-grade alloy construction for lighter loaded product types, a cast link belt with alloy link pins for heavier loaded product types, or a slat conveyor for specific gears or other shapes that lend themselves to this type of a large contact area style of belt. The belts are roll or skid supported (top and bottom) and the belt returns for higher temperature models are within the furnace for better fuel efficiency. Belt drives are electrical motor driven via drive drums or drive sprockets. These are continuous style furnaces and so products enter and exit through opposite ends. At the exit, an oil, polymer, high temperature salt, or water quench can be incorporated for the hardening process. For tempering, there is no quench involved. Traditional and boost diffuse carburizing–where zone separation is necessary for different process step temperatures or carbon potentials–can be performed in this type of furnace. Typical widths are 3.5 to 6 ft. but can be engineered up to 75 ft. in length. The operating temperature of higher temperature furnaces is typically 1400°F to 1950°F as this is a radiant/conduction style of heat transfer to the load. Lower temperature styles for tempering or stress relieving are from 350°F to 1400°F and typically incorporate convection fans.

Cascade quenching where small quantities of parts are dropped into the quench at one time is used. Separation of the oil from the furnace atmosphere is done via oil cascades which create a wall. Typical agitation in theses style of quenches are via pumps and nozzles pointed at the surface of the belt which retrieves the free falling parts and brings them up to the surface where they may be passed to a washing system prior to tempering. The oil can be heated via electric bayonet style heating elements and is cooled after quenching to return the oil temperature to the setpoint.

Surface’s extensive belt furnace line capabilities include dumpers, washers, tempers, quench tanks, and custom configurations.

Learn more about the full capabilities of Surface Belt Furnaces

Ceramic fiber or brick insulating systems

Maximum operating temperatures up to 2200°F

Electric, direct gas-fired (recuperative and regenerative) and radiant tube systems available

Controls meeting the requirements of AMS-2750 and CQI-9 can be provided as requested

Wide variety of belt designs

Gravity, robotic, or automatic loaders available

Roller or skid belt supports

Low energy consumption

Full line of companion equipment

Proprietary VF™ fan extends fan life by minimizing vibration and gives uniform atmosphere distribution

Annealing

Austempering

Brazing

Carbonitriding

Carburizing

Forging

Hardening

Normalizing

Reheating for Press Quench

Sintering

Stress Relieving

Temper

Partial processes list shown. Looking for something specfic, contact us.

Aerospace

Agricultural

Automotive

Bearings

Commercial Heat Treating

Fasteners

Gears

Hand & Power Tools

Off Road/Mining/Excavation

Powder Metals

Partial industries list shown. Looking for something specfic, contact us.

Aerospace Components

Aluminum

Bearings

Brass

Cast Iron

Casting

Chain

Copper

Fasteners

Forgings

Gears

Glass

Powdered Metal

Stainless Steels

Stampings

Steel

Titanium

Partial material and component list shown. Looking for something specfic, contact us.

Partial companion equipment list shown. Looking for something specfic, contact us.

Related Links:

Surface® is Your Source

CONTACT US TODAY, and let us show you the Value of Surface™

Ready to Get Started?

Please call us when you are ready to discuss a new furnace or maintain, upgrade or replace your furnace or any part of your furnace. At Surface, we look forward to helping you with any thermal processing needs.

Call Surface with the following information ready to initiate your furnace solution.

cycle

operation

hours per year

available space

operating temperature range

heat source

Give Us a Call