Controlled Atmosphere Carburizing Furnace Maintenance FAQs

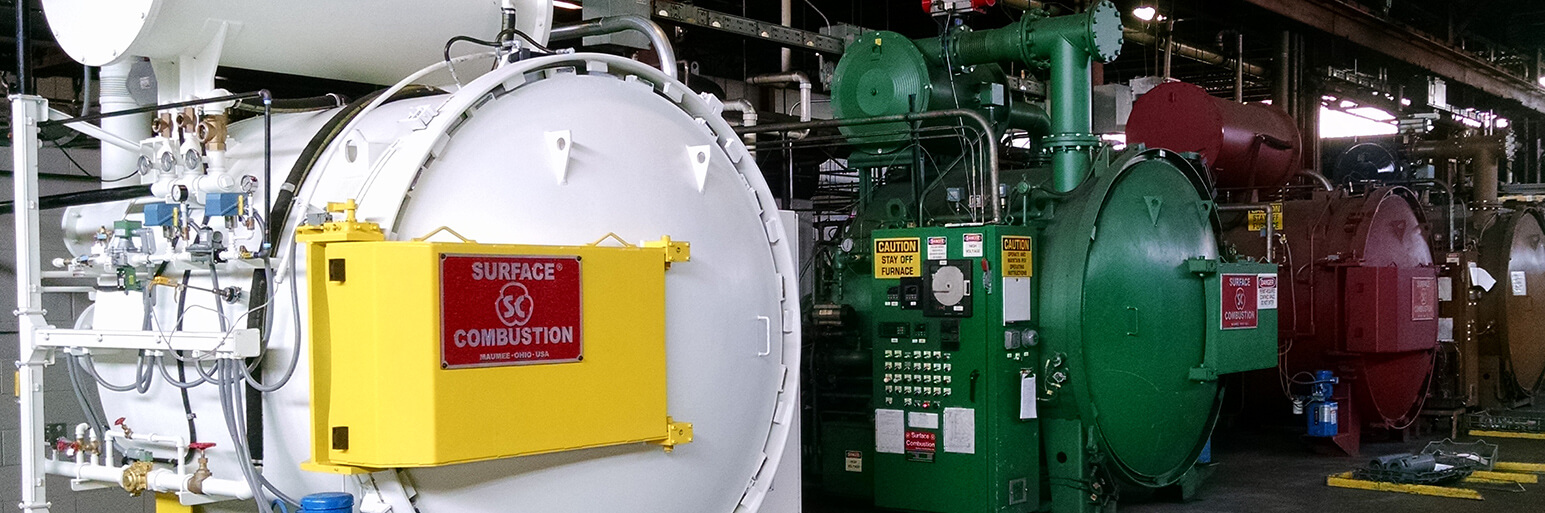

As the leading supplier of controlled atmosphere equipment for heat treating, Surface Combustion is your resource for preventative maintenance and furnace operation.

Read More >

As the leading supplier of controlled atmosphere equipment for heat treating, Surface Combustion is your resource for preventative maintenance and furnace operation.

Read More >

Surface Combustion is honored to be highlighted as a manufacturer in Ohio. This recognition is appreciated by Surface and our employees. Surface has two locations in Northwest Ohio and supports many manufacturers in Ohio. Read more by visiting the Ohio Secretary of State’s Website....

Read More >

The Chemical Weapons Demilitarisation Conference is an important date on Surface Combustion’s annual calendar. This international conference provides a unique forum that fosters discussion of developments in the world of Chemical Weapons, technology advancements, and solutions to intractable problems. Surface Combustion manufactures custom furnace solutions to support the destruction of chemical weapons. The CWD Conference supports the global effort to eliminate chemical weapons and fosters cooperation through the exchange of information and ideas relating to safe disposal. During the 2 days of presentations, panel sessions, poster displays and equipment demonstrations, there will be ample opportunity for discussion and networking. The conference is open to anyone with a relevant interest in CWD, and is attended by representatives of governments, industry, academia and the armed forces. The 23rd CWD Conference is organised by Dstl, the science inside UK defence and security, on behalf of the Ministry of...

Read More >

This year Surface Combustion is celebrating the 70th anniversary of the Allcase® Furnace and will continue events to mark this industry milestone at Forge Fair 2021! For 70 years, the Allcase batch integral quench furnace has been a trusted heat treating solution for our customers and we are excited to celebrate its success at this premier trade show for forging professionals! The Allcase success includes:

Surface® Combustion, Inc., a pioneer in the heat treatment industry since 1915, is celebrating the Allcase® Batch Integral Quench Furnace and its 70 years of successful heat treating. For 70 years, the Allcase batch integral quench furnace has been a trusted heat treating solution, meeting customer specified thermal processing and production requirements. Over 50% of heat treaters use the Allcase:

Surface® Combustion, Inc. has recently shipped a new Ion Nitriding Thermal Processing Furnace System for Watervliet Arsenal. Watervliet was familiar with Surface Combustion's multitude of furnace offerings and awarded a contract to Surface so they could again bring their processing capability in-house. Adding control to the supply chain for product was one of the many reasons Watervliet added a Ion Nitriding Thermal Processing Furnace System to their plant. Surface® Combustion has always placed a high value on customer relationships and believes that an equipment purchase is the beginning of something much more than a finite transaction. In fact, they have been working with the Watervliet Arsenal location for over 40 years. “It is always great to see customers coming back to Surface because they appreciate our incredible product lines as well as our engineering capabilities and long standing relationships," said Ben Bernard, VP of Marketing at Surface. The Surface® Combustion Ion Nitriding System,...

Read More >

Please see us at booth #1307

This year we are celebrating the 70th anniversary of the Allcase® furnace.

Register here to attend this exciting event!

Heat Treat is the premier conference and expo for heat treating professionals, attracting global innovators, researchers, influencers and decision makers from around the world. This year's conference and expo will feature:

2 1/2 days of face-to-face networking opportunities with approximately 200 heat treat exhibitors/companies. All of the top companies and big names in the heat treating industry will be represented!

Latest research and industry insights offered during more than 100 technical presentations

Continued co-location with Motion + Power Technology Expo 2021 with access to additional exhibitors, in the co-located exhibit hall

Student/emerging professionals initiatives, including free college student registration, Fluxtrol Student Research Competition and the new ASM Heat Treating Society Strong Bar Student Competition.

...

...

Surface® Combustion is pleased to offer On-Demand Virtual Trainings. When you have a question or a matter that needs attention, our engineers and technicians are available to address any of your specific equipment and knowledge requirements. We offer our on-demand virtual trainings to ensure your equipment is productive and efficient, and your downtime is limited. Even when times are uncertain, you can be assured that the Surface team is ready to help you with any of your thermal processing needs. To participate in a virtual training event, please contact Customer Service at (800) 537-8980....

Read More >

Gas Heated Vacuum Furnace Designs Lower Operating Costs for Vacuum Heat Treatment The advantages of vacuum heat treating are numerous and well documented. These advantages have traditionally been opposed by a few negatives such as furnace cost, overall operating cost, and in most cases, the cost of electricity as a utility. Typically, these negatives have been countered by the heat treater’s desire to provide vacuum processing to their customers or the requirement of certain materials to be vacuum processed. Over the history of this type of equipment, electric heating has been the primary heating source offered by manufacturers. This scenario has resulted in a well-established vacuum furnace installed base that uses electricity as the heating source. A Longer History Than You May Think Surface® Combustion initially investigated the use of natural gas heating in vacuum equipment as early as 1946 when a U.S. Patent was received for a fuel-fired vacuum furnace for the...

Read More >

Surface® Combustion, Inc. of Maumee, Ohio is proud to be an ongoing Diamond Sponsor of MTI and a Title Sponsor for the Furnaces North America (FNA) 2020 Virtual Show. The virtual event will be taking place Wednesday, September 30 - Friday, October 2, 2020. FNA 2020 is a melting pot of the best minds in heat treating with owners, executives, presidents, and CEOs from every facet in the heat treating operation in virtual attendance. “MTI events offer a great environment to connect with our customers, and FNA is no exception. This year will look slightly different but still, we are looking forward to connecting virtually with our commercial heat treaters,” says Stephanie Harcar, Marketing Coordinator. “Surface is excited to have a virtual booth where we can exhibit our furnace line including the new quick quench VersaQuench™ for non-ferrous heat treatment.” Surface will be hosting a "Combustion...

Read More >

Surface® Combustion is proud to be a Corporate Sponsor of Heat Treat Mexico 2020 presented by the ASM Heat Treating Society. This event which is being held in Queretaro March 3-5, 2020 is a perfect opportunity for networking and training specific to the thermal processing industry in Mexico. This year's conference will focus on the following topics:

Surface® Combustion is exhibiting at Fastener Fair USA 2020 in Charlotte, NC being held May 19th-20th. “Surface is a long-time supplier to the fastener industry providing equipment for pre-processing of rod and wire as well as post-processing including but not limited to through hardening, carburizing, and carbonitriding. We offer both continuous and batch solutions to meet your individual processing needs,” says Stephanie Harcar, Marketing Coordinator. Please visit us in Booth #829 to learn more about how Surface can help you achieve the ideal thermal processing solution for your fastener needs....

Read More >

Our Headquarters, located in Maumee, Ohio, is located in a business park called Arrowhead. This month, our association did a feature story on our business. Thank you Arrowhead! Please read more here....

Read More >

Surface® Combustion has always placed a high value on customer relationships. We believe that an equipment purchase is the beginning of something much more than a finite transaction. Our first-class customer service, rebuild/retrofit, and aftermarket parts departments are a testament to this way of thinking.

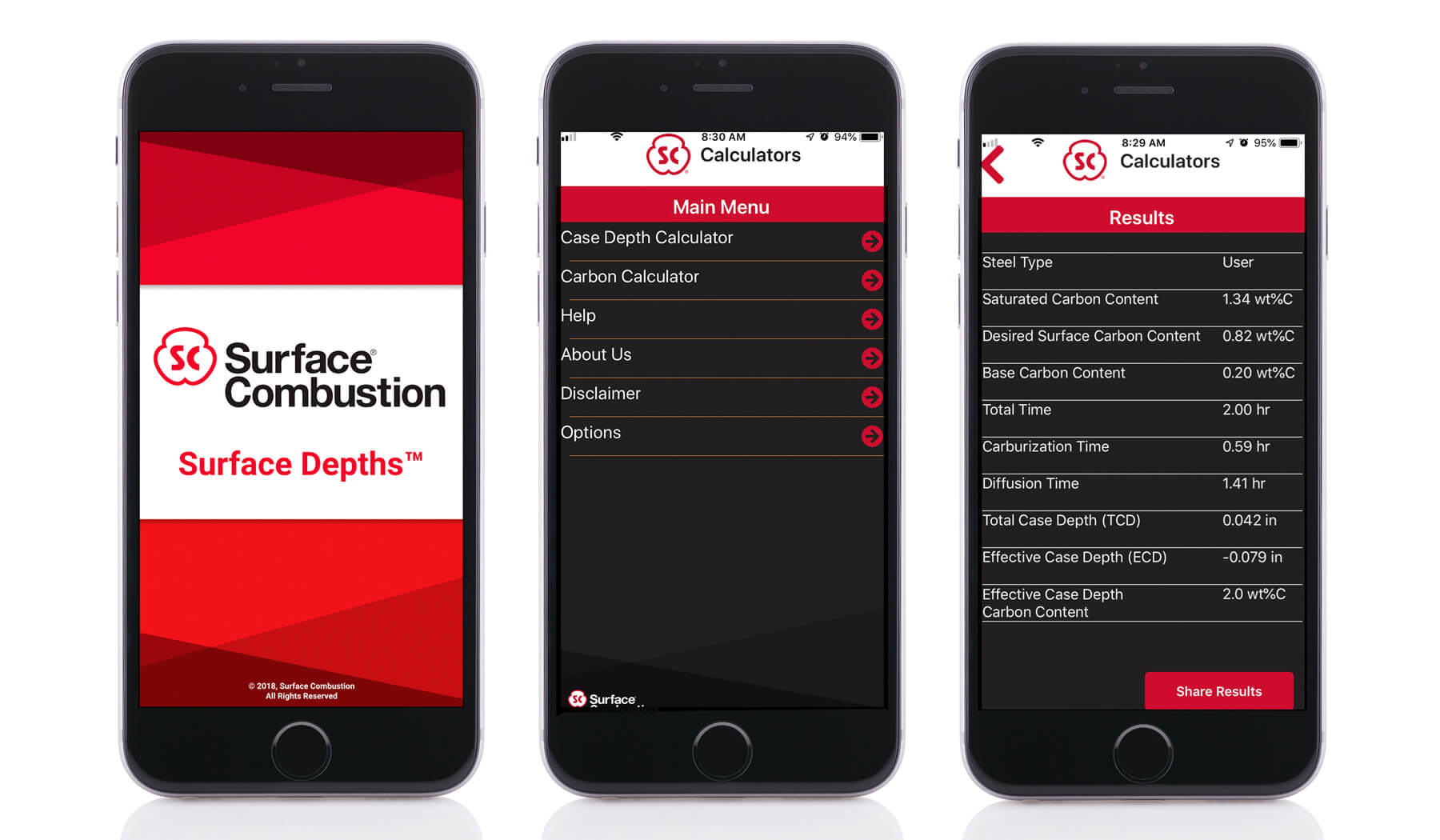

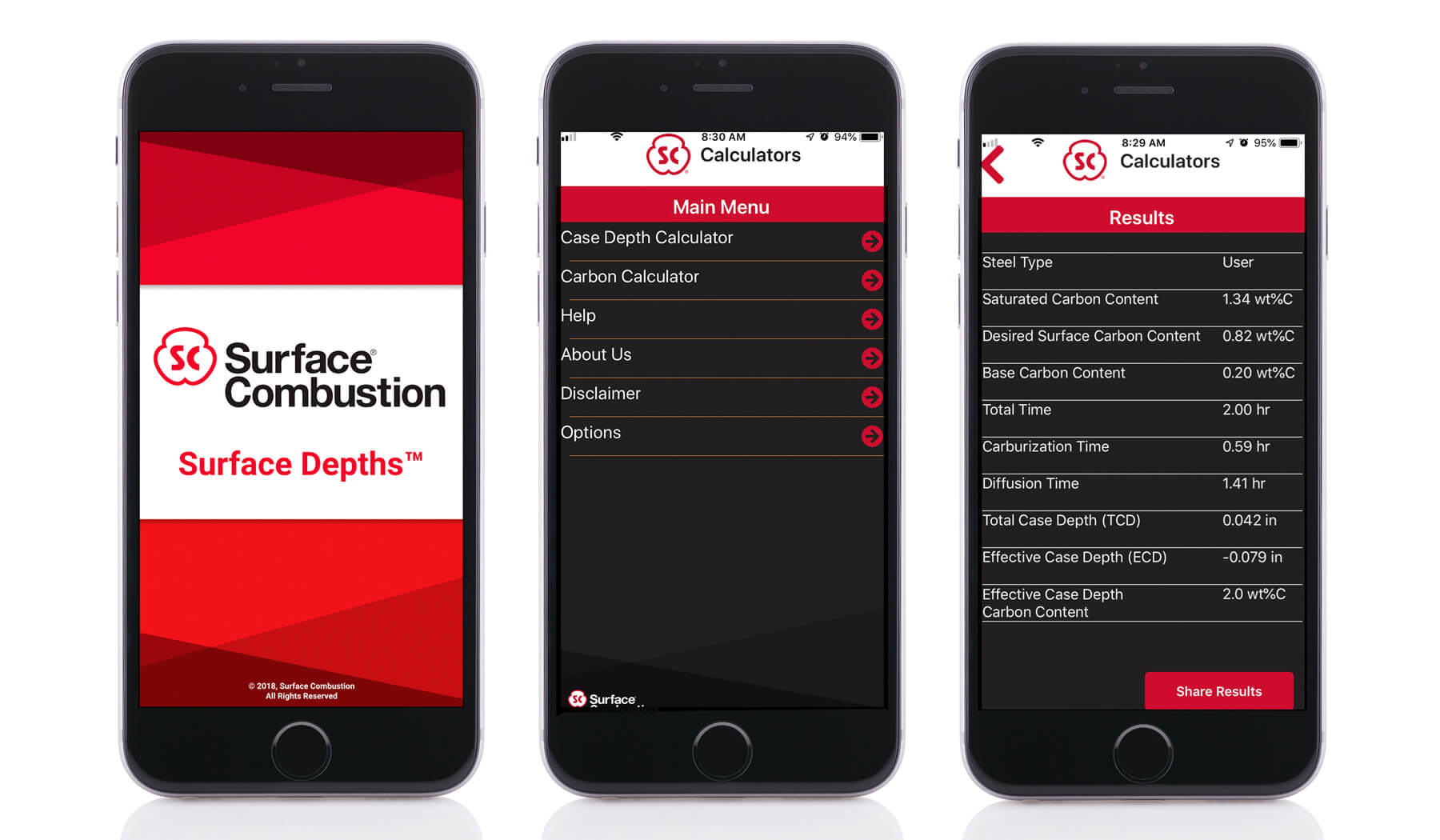

A few years back, Surface released a mobile application to calculate case depth. It was used by our engineers and customers alike to complete quick, accurate calculations from the shop floor. It quickly became evident that there was an opportunity to provide our customers with even more complementary calculators to aid in easier recipe adjustments. We are proud to introduce you to the new Surface Depths™ and hope that you find it as helpful as we do.

Current calculators include:

• Case Depth Calculator – This calculator provides a quick, back-of-the-envelope style estimate of case depth (or time to...

Current calculators include:

• Case Depth Calculator – This calculator provides a quick, back-of-the-envelope style estimate of case depth (or time to...

Maumee, Ohio: Surface Combustion supplied two (2) new Allcase® Batch Integral Quench Furnaces to Cambridge Heat Treating of Cambridge, Ontario. Cambridge also purchased two (2) used Allcase furnaces in Ontario. All four (4) Allcase furnaces are installed in the same line, along with a previously purchased 30”x30”x48” Allcase with top cool which are all serviced by Surface’s charge car, Uni-DRAW® Batch Tempering Furnaces, washers, and RX® Endothermic Atmosphere Gas Generator. Surface commissioned the new furnaces and continues to support the used equipment at its new home. The Allcase’s rugged design, ease of installation, and Surface’s aftermarket parts and service made this project a success. The 36”x48”x36” batch heat treat line greatly expands Cambridge’s capacity for carbonitriding, carburizing, neutral hardening, and added ferritic nitrocarburizing (FNC) and normalizing capacity with the atmosphere top cool chambers on the two (2) new Allcase furnaces. Says owner Peter Robbins, “We could not be happier with our...

Read More >