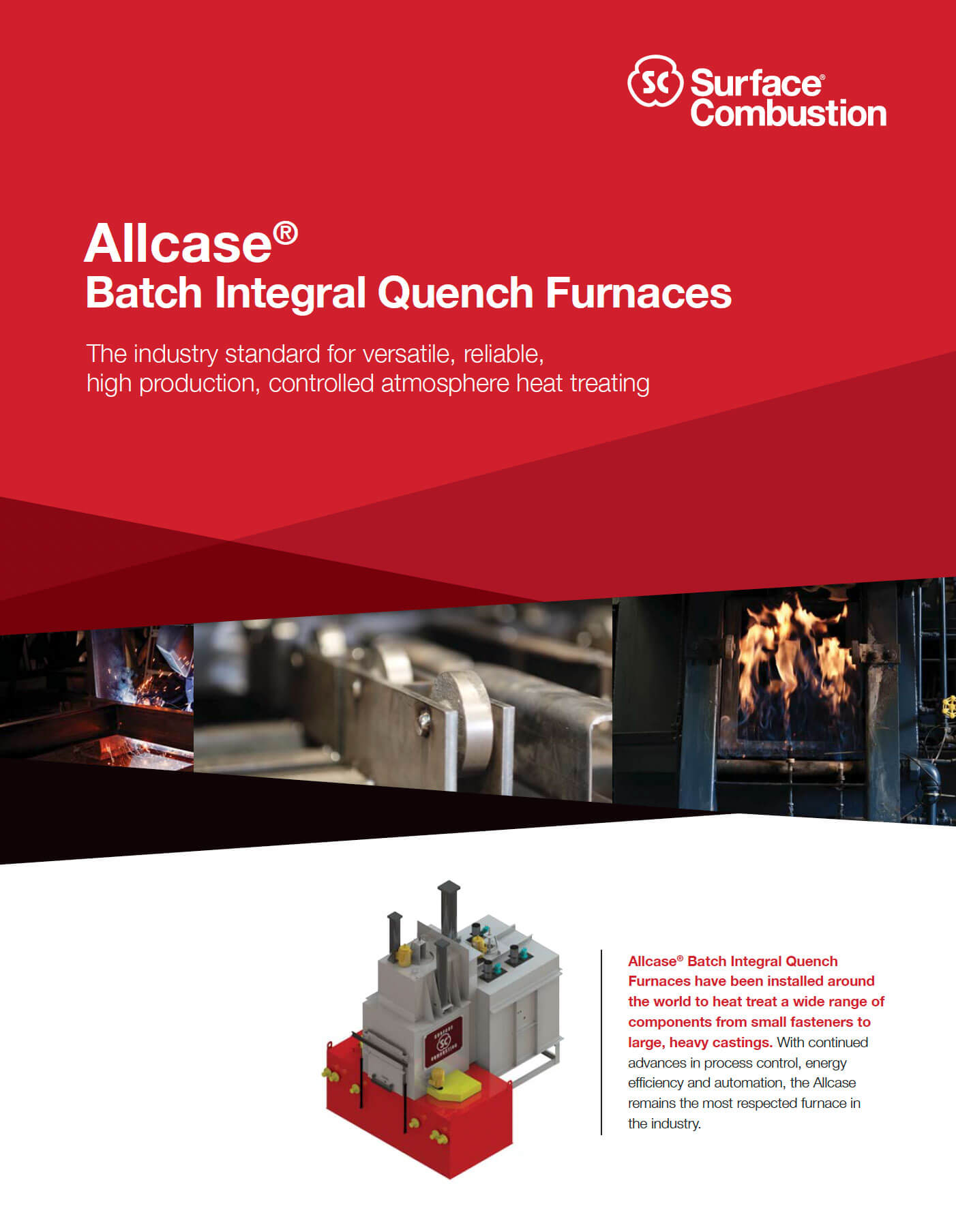

Allcase® Batch Integral Quench Furnace

Allcase® Batch Integral Quench Furnace

When you look to purchase anything in life, you always feel more comfortable when you go to the experts. As an industrial furnace manufacturer, Surface Combustion has more installed base and sells far more new Allcase® Batch Integral Quench Furnaces than any competitor in the US. Beginning in the early 1950’s, we introduced this innovative and versatile style of furnace to industry.

Surface® Combustion pioneered the development of the batch integral quench (BIQ) furnace design to serve a growing post World War II industrial boom which required many types of heat treating processes to be performed. The BIQ served this purpose as it easily performs through hardening, carburizing, carbonitriding, annealing and ferritic nitrocarburizing all in the same versatile furnace design. After thermal processing, the load is automatically transferred for oil, polymer or brine quenching or for slow cooling. Any of the forms of cooling are performed under an RX® (Endothermic Gas Generators), DX® (Exothermic Gas Generators), or Nitrogen protective atmosphere to protect the work surface against oxidation and also to improve the work piece appearance. This was a dramatic improvement at that time of introduction over transferring out into air before entering a quench medium. This revolutionized the heat treating industry and together with the stated atmospheres enabled the future of boost/diffuse carburizing, carbon control and all the instrumentation and sensors that grew out of this invention.

Surface named this miracle furnace the Allcase.

Today’s Allcase looks similar but actually is much different than that of its grandfather from the 1950s. It is more automated and the physical load sizes and weights are much larger. The most common size today is the 36-48-36 which is more than four times larger in volume than 65 years ago. In addition, improvements in insulation, gas and electric heating technologies, recuperation, sensors and atmosphere control, quench tank volumes, agitation and oil heating and cooling technologies all make the Allcase a revolutionary piece of equipment even today. Surface still likes brick refractories which adds to process stability, especially in the carburizing process. Heating can be vertically or horizontally gas fired radiant tubes or various electric heating designs. Our patented Proelectric® design offers great uniformity and great life in challenging carbon bearing atmospheres.

Commercial heat treaters love the versatility as they never know what their next work coming in the door may be. Allcase equipment is intended to be grouped together with other Allcases and the required batch auxiliary equipment to become a heat treating cell of sorts.

Automation of the Allcase line motions and actions, even to the extent of bar code readers to send any given workload through a determined path of heat treating equipment and with all of the required data collection, is commonplace.

Learn more about the full capabilities of our Allcase® Batch Integral Quench Furnace

Standard Sizes

| Width | 24″ | 30″ | 36″ | 36″ | 36″ | 42″ |

| Length | 36″ | 48″ | 48″ | 72″ | 72″ | 72″ |

| Height | 24″ | 30″ | 36″ | 36″ | 42″ | 42″ |

Maximum operating temperatures up to 1950°F

Multiple gas fired heating systems available including vertical and horizontal radiant tube configurations.

Electric heating systems available including Proletric® style and canned element style

Roller rail or skid hearth systems

Oil, water, polymer, and brine quench systems available

Atmosphere Cool Chambers (Top Cool) available

Numerous automation and networking controls available

Allcase® family also includes RTB (Radiant Tube Box) and ACT (Radiant Tube Box Furnace with Atmosphere Top Cool)

Proprietary VF™ fan extends fan life by minimizing vibration and gives uniform atmosphere distribution

Annealing

Black Oxide

Carbon Restoration

Carbonitriding

Carburizing

Ferritic Nitrocarburizing (FNC)

Hardening

Marquenching

Normalizing

Solution Treatments

Spheroidizing

Stress Relieving

Partial processes list shown. Looking for something specfic, contact us.

Aerospace

Agricultural

Aluminum Processing

Automotive

Bearings

Castings

Commercial Heat Treating

Fasteners

Forging

Gears

Government Furnace Supplier

Hand & Power Tools

Off Road/Mining/Excavation

Oil & Gas

Powder Metals

Sporting Goods

Trucking/Bus/Rail

Wind Power

Partial industries list shown. Looking for something specfic, contact us.

Aerospace Components

Bearings

Cast and Ductile Iron

Casting

Chain

Copper

Crankshafts

Cutlery

Fasteners

Forgings

Gears

Gun Barrels

Hand Tools

Pinions

Powdered Metal

Rock Bits

Shafts

Springs

Stainless Steels

Steel

Tool Steels

Tools

Partial material and component list shown. Looking for something specfic, contact us.

Temper

Atmosphere Generator

Air Cool Station

Atmosphere Cooling Systems

Control Systems for Industrial Heat Treat Furnaces

Uni-DRAW® Batch Tempering Furnaces

Trays/Baskets/Fixtures

Loading Cars

Load/Unload Tables

Partial companion equipment list shown. Looking for something specfic, contact us.

Surface® is Your Source

CONTACT US TODAY, and let us show you the Value of Surface™

Ready to Get Started?

Please call us when you are ready to discuss a new furnace or maintain, upgrade or replace your furnace or any part of your furnace. At Surface, we look forward to helping you with any thermal processing needs.

Call Surface with the following information ready to initiate your furnace solution.

cycle

operation

hours per year

available space

operating temperature range

heat source

Give Us a Call