Why Heat Treat Leaders Choose RX® Generators

Manufacturing engineers and plant managers select RX® Generators for compelling operational advantages:

Our modular design architecture accommodates varying production demands through scalable tube configurations. Single to five-tube generators provide flow rates from 2,000 to 12,000 CFH, with exceptional 6:1 turndown capability maintaining consistent gas composition throughout the operating range. Individual reaction tubes operate independently, allowing selective shutdown for maintenance while maintaining continuous production. Compatible with all major furnace types including Allcase® batch integral quench furnaces, belt furnaces, pusher tray systems, and rotary hearth configurations.

Surface RX generators are engineered for decades of continuous operation with minimal downtime. Our customers consider these systems as reliable as public utilities. Key reliability features include:

- Online burnout capability for tube reconditioning without system shutdown

- Backup mixture pump for seamless maintenance transitions

- Hot-swappable oxygen sensors for uninterrupted operation

- Heavy-wall, heat-resistant cast alloy reaction tubes designed for extended service life

- Proven air/gas mixing system with positive displacement pumps ensuring consistent product gas chemistry

Precise atmospheric control ensures repeatable metallurgical results across all production batches. Our proprietary ESA® dew point sensor system employs dual automotive oxygen probes for accurate carbon potential control. Advanced diagnostics monitor individual retort performance including:

- Equalized flow distribution across all tubes

- Temperature uniformity within each reaction chamber

- Real-time gas composition verification

- Predictive maintenance alerts through AP™ Endo diagnostic tools

Modular construction optimizes energy consumption by operating only the required number of tubes based on demand. High-efficiency thermal insulation minimizes heat loss while ENDOQUENCH® air cooling systems lock atmospheric chemistry and prevent carbon precipitation in distribution piping. Recuperative heating systems and optimized catalyst bed design maximize conversion efficiency while reducing fuel consumption.

Surface Combustion maintains the industry’s largest inventory of critical spare parts including RX alloy retorts, catalyst, and refractory components. Our dedicated aftermarket team provides:

- 24/7 technical support and troubleshooting

- Comprehensive field service and installation support

- Preventive maintenance programs tailored to your operation

- Equipment rebuilds and upgrades to extend service life

- Process optimization consulting and metallurgical support

Learn more about the full capabilities of our RX® Endothermic Gas Generators

Metallurgical Excellence Through Generated Atmospheres in Heat Treatment

RX Gas Generators excel in diverse thermal processing applications

- Annealing

- Brazing

- Carbonitriding

- Carbon restoration

- Carburizing

- Ferritic nitrocarburizing (FNC)

- Neutral hardening

- Sintering

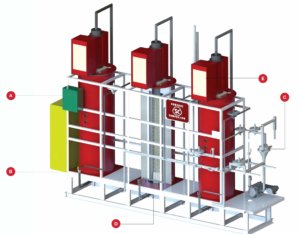

Surface Atmosphere Generator System Detail

A. Main Generator Construction

- Vertical cylindrical casings with insulation

- Mounted on raised steel frame

B. Reaction Tube Assembly

- Heavy-wall heat-resistant cast alloy tubes

- Filled with special catalyst material

- Removable through generator assembly top

C. Reaction Gas Mixing System

- Controls air/natural gas ratio flows

- Positive displacement mixture pump included

- Oil recirculation reduces maintenance needs

D. Heating System

- Ring burners at tube bottom

- Electronic ignition with flame supervision

- Hot gases flow vertically upward

- Flue gases exhaust through top

E. Product Gas Cooler

- Water/air coolers at tube top

- Quench gas exiting reaction tube

- Freeze product gas reactions

- Controls air/natural gas ratio flows

- Positive displacement mixture pump included

- Oil recirculation reduces maintenance needs

Technical Specifications

Generator Capacities

- RX-1S/1T: 2,000-3,000 CFH (57-85 m³/hr)

- RX-2S/2T: 4,000-6,000 CFH (114-170 m³/hr)

- RX-3S/3T: 6,000-9,000 CFH (170-255 m³/hr)

- RX-4S/4T: 8,000-12,000 CFH (227-340 m³/hr)

- RX-5T: 12,000 CFH (340 m³/hr)

Atmospheric Composition

- 40% Nitrogen (N₂)

- 40% Hydrogen (H₂)

- 20% Carbon Monoxide (CO)

- Trace amounts: CO₂, CH₄, H₂O

Applications and Processes

Primary Heat Treating Processes

- Gas carburizing and boost/diffuse carburizing

- Carbonitriding and ferritic nitrocarburizing (FNC)

- Carbon restoration and neutral hardening

- Bright annealing and stress relieving

- Sintering and brazing operations

Compatible Furnace Systems

- Allcase® Batch Integral Quench Furnaces

- Mesh belt and cast belt continuous furnaces

- Pusher tray and roller hearth systems

- Rotary hearth and retort furnaces

- Pit furnaces and box-type batch systems

Control Systems and Instrumentation

ESA® Dew Point Control System

- CQI-9 capable atmospheric monitoring

- Dual oxygen probe redundancy for enhanced reliability

- Real-time dew point and carbon potential control

- Digital communications with large HMI displays

Advanced Diagnostic Options

- Individual retort flow monitoring

- Temperature profiling for each reaction tube

- Predictive maintenance scheduling

- Historical trending and process documentation

Available Control Platforms

- ESA® 8200: Advanced PLC with comprehensive HMI

- C6™-E: Economic micro PLC with essential controls

- ESA® 3200: Single-loop controllers for basic applications

Frequently Asked Questions About RX® Endothermic Gas Generators

What is an endothermic gas generator?

An endothermic gas generator produces a protective atmosphere by reacting natural gas and air over a heated catalyst. The RX® generator creates a consistent atmosphere containing approximately 40% nitrogen, 40% hydrogen, and 20% carbon monoxide, with trace amounts of CO₂, CH₄, and H₂O.

How do I determine the right size RX® generator for my operation?

Standard RX® generators are available to produce from 2,000 to 15,000 ft³ per hour. Specific models include: RX-1S/1T (2,000-3,000 CFH), RX-2S/2T (4,000-6,000 CFH), RX-3S/3T (6,000-9,000 CFH), RX-4S/4T (8,000-12,000 CFH), and RX-5T (12,000 CFH). The modular design allows for expansion based on production demands.

What’s the difference between electric and direct gas-fired RX® generators?

Both electric and direct gas-fired systems are available. The source materials do not specify the detailed differences between these heating methods.

What is the typical atmospheric composition from an RX® generator?

Standard composition is approximately 40% nitrogen, 40% hydrogen, 20% carbon monoxide, with trace amounts of CO₂, CH₄, and H₂O.

What control system options are available?

Available control platforms include the ESA® 8200 (advanced PLC with comprehensive HMI), C6™-E (economic micro PLC with essential controls), and ESA® 3200 (single-loop controllers for basic applications). ESA® controls use reliable oxygen probe-based automatic dew point controls.

What heat treating processes can use RX® generated atmospheres?

RX® generators support gas carburizing and boost/diffuse carburizing, carbonitriding and ferritic nitrocarburizing (FNC), carbon restoration and neutral hardening, bright annealing and stress relieving, sintering and brazing operations, annealing, and normalizing.

What furnace types are compatible with RX® generators?

RX® generators are compatible with all major furnace types, including Allcase® batch integral quench furnaces, mesh belt and cast belt continuous furnaces, pusher tray and roller hearth systems, rotary hearth and retort furnaces, and pit furnaces and box-type batch systems.

How do I control carbon potential with an RX® generator?

Carbon potential is controlled through the ESA® dew point sensor system using dual automotive oxygen probes for accurate carbon potential control. The system provides real-time dew point and carbon potential control with CQI-9 capable atmospheric monitoring.

Can I perform maintenance without shutting down gas production?

Yes, the modular design allows on-line maintenance (burn out) functions while individual or multiple tubes are producing gas. Individual reaction tubes operate independently, allowing selective shutdown for maintenance while maintaining continuous production.

How does the turndown capability benefit my operation?

RX® generators feature automatic turn down functions up to 6:1 turn down which eliminates venting excess gas. The exceptional 6:1 turndown capability maintains consistent gas composition throughout the operating range.

How does the positive displacement mixture pump improve reliability?

The positive displacement mixture pump is included in the reaction gas mixing system and controls air/natural gas ratio flows. Oil recirculation reduces maintenance needs.

How does the ENDOQUENCH® cooling system work?

ENDOQUENCH® air cooling systems lock atmospheric chemistry and prevent carbon precipitation in distribution piping. Air and water gas cooling systems are available.

What safety features are included with RX® generators?

Standard safety features include electronic ignition with flame supervision. The heating system uses ring burners at tube bottom with electronic ignition and flame supervision.

How do I set the delivery pressure on an RX® generator?

Maximum flow, minimum flow, and delivery pressure all need to be checked when any adjustments are made. Consult your generator operating instructions for the correct procedure for these settings. Delivery pressure is set by removing the top cover from the RP regulator (not the small cover that covers the stop bolt, but the larger cover that the stop bolt is screwed in to). Looking down inside the regulator, you will see an adjustment disk with a large screwdriver slot in it. The main regulator threaded rod comes through the middle of this adjustment disk. Turning this disk will adjust the delivery pressure. Make sure the generator is at the vent position and that the vent valve is about half closed. Consult your operating instructions for a detailed procedure.

How long do the reaction tubes typically last?

RX® generators use heavy-wall, heat-resistant cast alloy reaction tubes designed for extended service life. The tubes are removable through generator assembly top for maintenance.

What catalyst is used and how often does it need replacement?

RX® generators use special catalyst material that fills the reaction tubes. Surface Combustion maintains the industry’s largest inventory of critical spare parts including catalyst.

What maintenance is required for optimal performance?

Key maintenance includes online burnout capability for tube reconditioning without system shutdown. On-line backup mixture pumps are available for maintenance transitions. Advanced Diagnostic predictive maintenance tool options are available.

What technical support is available after installation?

Surface Combustion provides 24/7 technical support and troubleshooting, comprehensive field service and installation support, preventive maintenance programs tailored to your operation, equipment rebuilds and upgrades to extend service life, and process optimization consulting and metallurgical support.

How do I change catalyst and alundum spheres on an RX® generator?

Consult the procedure in your generator operating instructions. Contact Surface if you need a copy.

How do I perform a burnout on a tube of an RX® generator?

Consult the burnout procedure in your generator operating instructions. Contact Surface if you need a copy.

What industries typically use RX® endothermic gas generators?

RX® generators serve aerospace, agricultural, automotive, bearings, commercial heat treating, fasteners, hand & power tools, off road/mining/excavation, oil & gas, powder metals, trucking/bus/rail, and wind power industries.

CASE STUDY: RX® Endothermic Atmosphere Gas Generators for Heat Treating

Standard Sizes are available to produce from 2000 to 15,000 ft³ per hour

Ceramic fiber insulating systems allow ramped heat up or cool down

Electric and direct gas fired systems available

Automatic turn down functions up to 6:1 turn down eliminates venting excess gas

Modular design allowing on line maintenance (burn out) functions while individual or multiple tubes are producing gas

Air and water gas cooling systems available

On-line backup mixture pumps available

Reliable oxygen probe based, automatic dew point controls

Advanced Diagnostic predictive maintenance tool options

ESA® controls use reliable oxygen probe-based automatic dew point controls

Annealing

Carbon Restoration

Carbonitriding

Carburizing

Ferritic Nitrocarburizing (FNC)

Hardening

Normalizing

Sintering

Solution Treatments

Stress Relieving

Partial processes list shown. Looking for something specfic, contact us.

Aerospace

Agricultural

Automotive

Bearings

Commercial Heat Treating

Fasteners

Hand & Power Tools

Off Road/Mining/Excavation

Oil & Gas

Powder Metals

Trucking/Bus/Rail

Wind Power

Partial industries list shown. Looking for something specfic, contact us.

Cast and Ductile Iron

Powdered Metal

Stainless Steels

Steel

Tools

Partial material and component list shown. Looking for something specfic, contact us.

Partial companion equipment list shown. Looking for something specfic, contact us.

Surface® is Your Source

CONTACT US TODAY, and let us show you the Value of Surface™