Power Convection® Vacuum Furnaces

Power Convection® Vacuum Furnaces

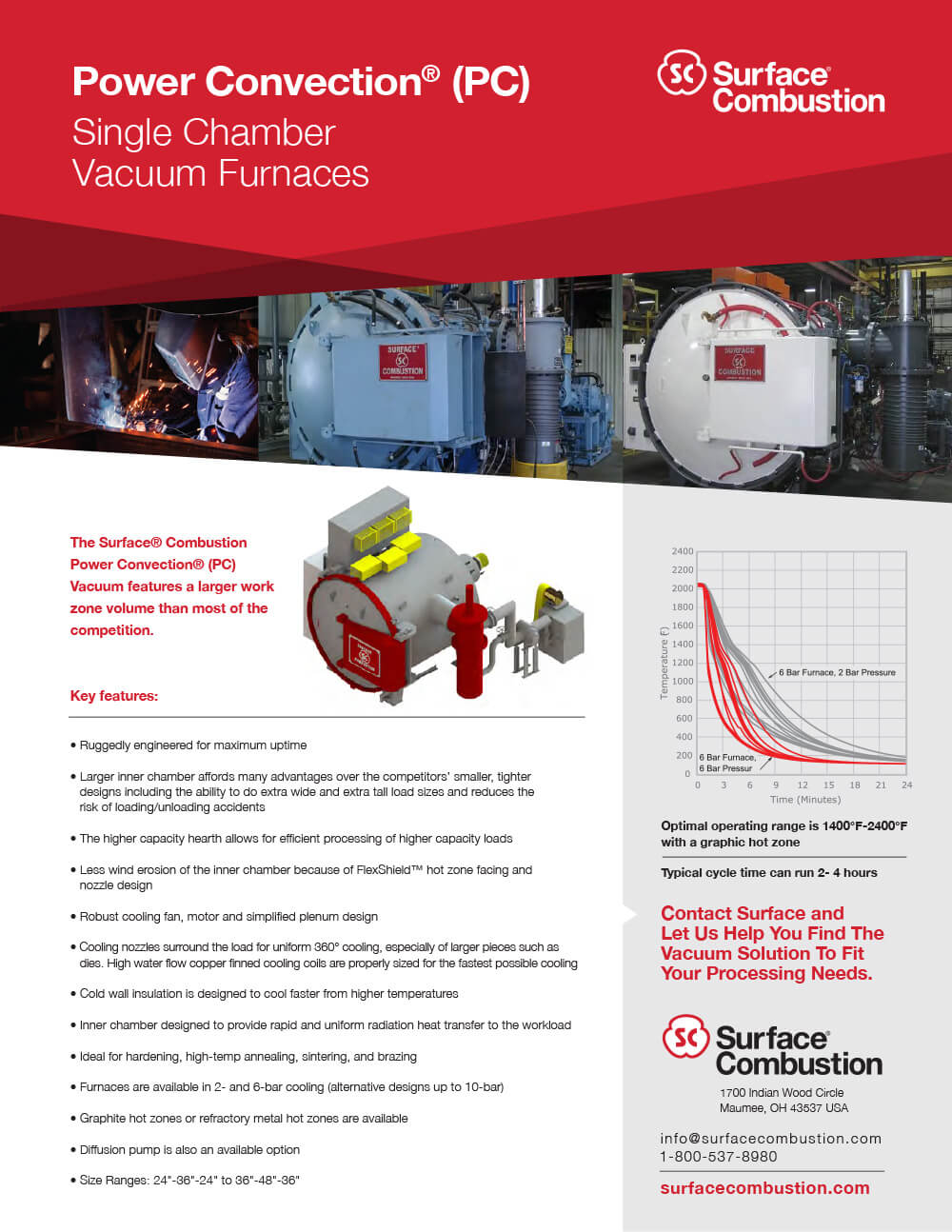

When you look to purchase anything in life, you always feel more comfortable when you go to the experts. As a vacuum furnace manufacturer, Surface Combustion has 30 years of experience with 2-bar and, more recently, 6-bar vacuum furnace technology. This gives our customers the confidence level that our technology will work every time. This innovative and versatile style of horizontal vacuum furnace is an industry workhorse.

Surface® Combustion took our conventional water jacketed and cubed inner chamber design and concepted the cylindrical inner chamber with graphite heating elements that uniformly radiate to each other providing a wall of heat. This gives the workload a very uniform band of heating through the operating temperature range which is typically from 1400°F to 2400°F.

Heating is performed under a vacuum, the level of which is determined by the pumping system selected. For vacuum levels down to 10 microns, a combination mechanical piston pump with a blower is used. If higher vacuum levels are required, a diffusion pumping system operating in conjunction with the base pumping systems would be used.

The inner chamber is typically graphite-based rigid board and/or felt with machined graphite resistance heating elements. All are mounted within a stainless steel inner chamber frame which allows for multiple rebuilds within the same frame. The heating elements are powered with a low voltage, high current variable reactance transformer.

After the thermal heating cycle, the furnace is backfilled with inert gas from a vacuum to a positive pressure of 2 or 6 bar. Once backfilled, a high capacity and high convection fan recirculates this hot inert gas through internal cooling coils (heat exchangers) to rapidly cool the load. The access door is hydraulically clamped in place with a locking ring assembly.

The goal in vacuum processing is to cool the workload back down to ambient temperature to avoid workload discoloration and oxidation.

The Power Convection vacuum furnace is best suited for higher temperature processing where radiant heat is the dominant heat transfer mechanism. The best applications are those over 1400°F. This is the transition point of the effectiveness of radiant heating versus convection heating. Typical processes include hardening, annealing, sintering and brazing.

Learn more about the full capabilities of our Power Convection® Furnace

Specifications:

| 24-36-24 rated at 1,500 lbs. Gross Load | 36-48-36 rated at 4,000 lbs. Gross Load | 36-72-36 Rated at 8,000 lbs. Gross Load |

Ruggedly engineered for maximum uptime

Larger inner chamber affords many advantages over competitors’ smaller, tighter designs including the ability to do extra wide and extra tall load sizes and reducing the risk of loading/unloading accidents

Inner chamber designed to provide rapid and uniform radiation heat transfer to the workload

Higher capacity hearth allows for efficient processing of heavy loads

FlexShield™ hot zone facing and nozzle design reduce wind erosion of the inner chamber

Robust cooling fan with a powerful motor; plenum designed to efficiently circulate windflow

Cooling nozzles surround the load for uniform 360° cooling, especially for larger pieces such as dies. High water flow copper finned cooling coils are sized for the fastest possible cooling

Cold wall insulation is designed to cool faster from higher temperatures

Ideal for hardening, high-temp annealing, sintering, and brazing

Furnaces are available in 2- and 6-bar cooling (alternative designs up to 10-bar)

Graphite hot zones or refractory metal hot zones are available

Diffusion pump option available

Partial processes list shown. Looking for something specfic, contact us.

Partial industries list shown. Looking for something specfic, contact us.

Copper

Stainless Steels

Steel

Super Alloys

Titanium

Partial material and component list shown. Looking for something specfic, contact us.

Partial companion equipment list shown. Looking for something specfic, contact us.

Surface® is Your Source

CONTACT US TODAY, and let us show you the Value of Surface™

Ready to Get Started?

Please call us when you are ready to discuss a new furnace or maintain, upgrade or replace your furnace or any part of your furnace. At Surface, we look forward to helping you with any thermal processing needs.

Call Surface with the following information ready to initiate your furnace solution.

cycle

operation

hours per year

available space

operating temperature range

heat source

Give Us a Call