Why Heat Treat Leaders Choose the Allcase® System

Manufacturing engineers and plant managers select the Allcase® batch integral quench furnace for compelling operational advantages:

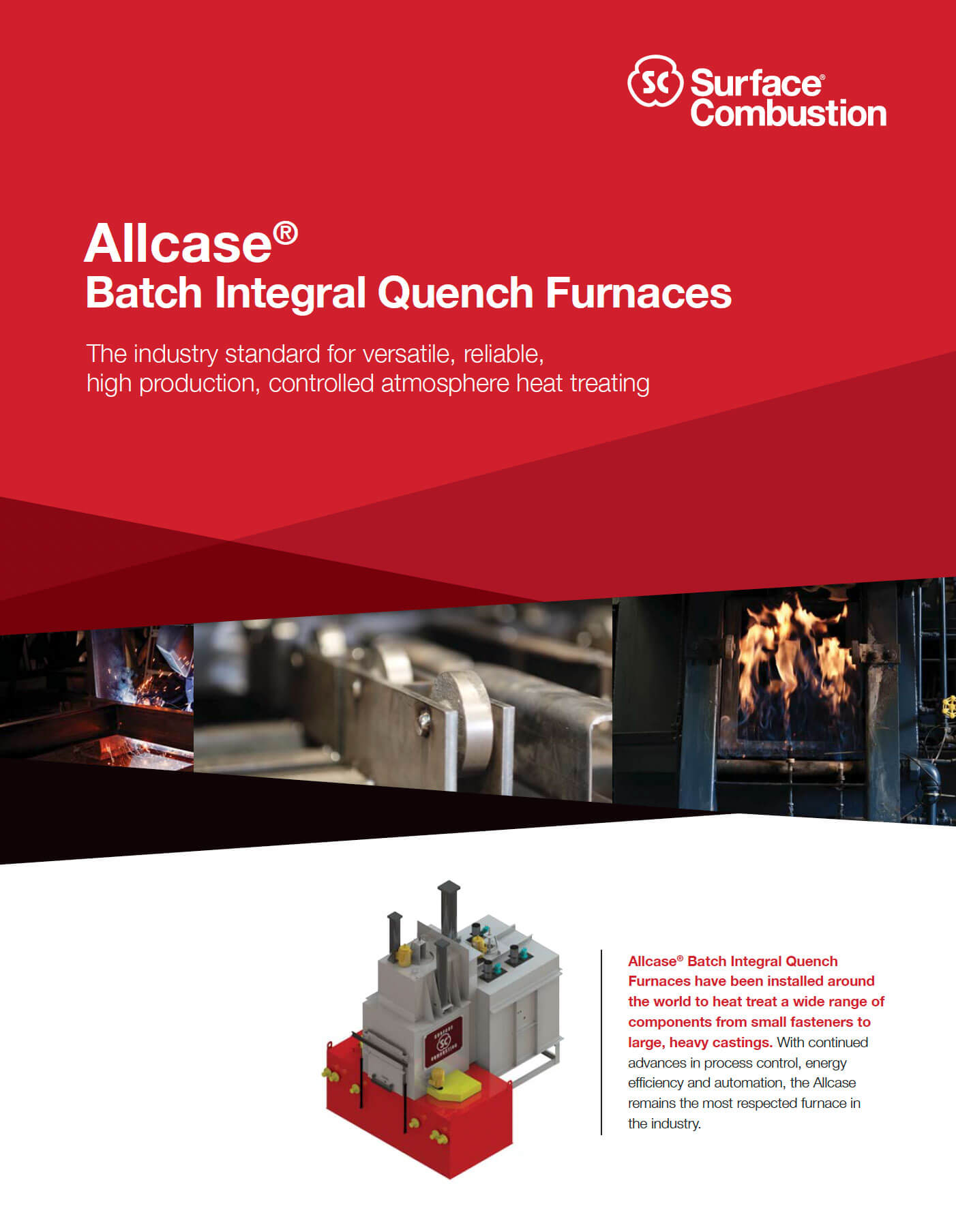

A single furnace can perform multiple thermal processes, adapting to changing production requirements without additional capital investment.

Surface Combustion’s robust construction and standardized designs minimize downtime and maintenance requirements.

Precise atmosphere and temperature control ensure repeatable case depths, hardness profiles, and microstructures.

Standard recuperation systems and optional advanced controls minimize fuel consumption and operating costs.

Surface Combustion’s aftermarket parts inventory and service team ensure decades of productive operation.

From initial process development through equipment commissioning and lifetime support, Surface Combustion provides the expertise to maximize your heat treatment capabilities.

Learn more about the full capabilities of our Allcase® Batch Integral Quench Furnace

Metallurgical Versatility Through Multiple Processes in One Furnace

The Allcase® excels in diverse thermal processing applications:

- Annealing

- Carbonitriding

- Carbon Restoration

- Carburizing

- Marquenching

- Neutral Hardening

- Normalizing

- Spheroidizing

- Stress Relieving

- Triniding™/ Ferritic Nitrocarburizing

Production Efficiency Driven By Automated Material Handling Solutions

Available in six standard work sizes and four configurations, the Allcase® can be fully automated with companion equipment for complete processing.

Our handling systems include:

Extended Reach™ System, an operator-initiated load movement through vestibule, heating chamber, and quench tank via charge car or table.

Controls and Automation

Available in 6 standard effective work sizes and 4 different configurations, an Allcase line can be fully automated with companion equipment to process loads from start to finish.

Thermal Uniformity Through Advanced Heating and Quenching Technology

Surface’s Allcase® systems incorporate efficient gas heating with vertical “U” tubes or horizontal Trident® tubes, or electric heating with patented Proelectric® elements. The optimized quench system and double deck elevator enhance productivity by allowing simultaneous quenching and charging.

Process Optimization Utilizing Tailored Heat Treating Solutions

Customization options include automation, extended reach operation, top cool chambers, hot oil quenching, and multiple atmosphere options.

The Allcase® delivers proven flexible processing of diverse components, rugged construction for heavy loads, consistent long-term performance, and efficient operation with recuperated combustion systems.

Case Hardening Options for Heat Treating Steel

Uncover the processes and furnaces used for the steel case hardening solutions. Ben Bernard from Surface® Combustion, Inc. describes these options and reveals the advantages and disadvantages of the various options.

Ideal For:

- Castings

- Forgings

- Gears

- Hand tools

- Shafts

- Machined components where quality and process flexibility are essential.

Frequently Asked Questions About Batch Integral Quench Furnaces

What is a batch integral quench furnace?

A batch integral quench furnace (BIQ) is a heat treating system that allows controlled atmosphere thermal processing followed by direct quenching under protective atmosphere. The quench tank is integrated with the furnace, minimizing transfer time and oxidation risk.

How do I choose the right size furnace for my operation?

Consider your typical and maximum workload dimensions and weight, along with throughput requirements. Standard effective work sizes range from 24″×36″×24″ handling 1,500 lbs to 42″×72″×42″ handling 7,000 lbs, but your specific parts and production volume will determine the optimal size.

What’s the difference between gas-fired and electric heating for these furnaces?

Gas-fired furnaces (with vertical or horizontal radiant tubes) typically have lower operating costs in regions with inexpensive natural gas, while electric furnaces offer more precise temperature control and may be preferred where gas availability is limited or electricity costs are favorable.

Can I expand my heat treating capacity over time?

Yes, BIQ furnaces are designed for modular expansion. You can start with a basic furnace and add companion equipment (tempering furnaces, washers, charge cars, etc.) as production demands increase.

What heat treating processes can I perform in a batch integral quench furnace?

BIQ furnaces can perform multiple processes including hardening, annealing, normalizing, gas carburizing, carbon restoration, carbonitriding, marquenching, spheroidizing, stress relieving, and ferritic nitrocarburizing (FNC).

How do I control carbon potential during carburizing?

Carbon potential is controlled through proper atmosphere composition and regulation. Modern control systems use oxygen probes, gas analysis, and advanced algorithms to maintain precise carbon potential throughout the process.

Can I process different types of steel in the same furnace?

Yes, BIQ furnaces are versatile and can process various steel types. Different recipes can be programmed for specific materials, and cleaning cycles can be implemented when switching between certain material types.

What quenching options are available?

Standard BIQ furnaces use oil quenching, but systems can be designed for polymer quenching, hot oil quenching (up to 350°F/176°C), or salt quenching. Many furnaces also offer top cooling chambers for controlled atmosphere cooling without quenching.

What facility requirements do I need for installation?

Requirements include adequate floor space, utilities (gas and/or electricity, water, compressed air), ventilation, and foundation capacity to support the equipment weight. Oil handling and disposal systems are also necessary.

What type of atmosphere control do I need?

Atmosphere requirements depend on your processes. Options include endothermic gas generators, exothermic gas generators, or nitrogen/methanol systems. The furnace control system will regulate the atmosphere based on the specific heat treating process.

How automated can these furnaces be?

BIQ furnaces can range from manually operated to fully automated systems. Options include operator-initiated Extended Reach™ systems, semi-automated System #1™ configurations, and fully automated Push/Push systems with automated charge cars.

What control systems are available?

Modern BIQ furnaces use PLC-based controls with options ranging from basic temperature and atmosphere control to advanced SCADA systems with recipe management, historical trending, lot tracking, and maintenance scheduling.

What temperature uniformity can I expect?

Properly designed BIQ furnaces achieve excellent temperature uniformity through high-velocity recirculation fans and optimized heating systems. Specific uniformity values depend on the furnace size and configuration.

How long does a typical heat treating cycle take?

Cycle times vary widely based on the process, material, and part geometry. Carburizing cycles can range from 2-20+ hours, while hardening cycles might run 1-4 hours. Your specific requirements will determine actual cycle times.

What routine maintenance is required?

Key maintenance areas include the recirculation fan, heating elements or radiant tubes, door seals, quench system, and atmosphere control components. Preventative maintenance programs typically include scheduled inspections and replacement of wear items.

How long should a furnace last?

With proper maintenance, BIQ furnaces can provide decades of service. Many installations over 30 years old are still in productive operation.

Why is my load getting hung up? Any easy checks?

The most common cause of a load hanging up are roller rails that are warped or uneven. Over time, these rails can deform from the load weight and temperature. Sight down the rails from outside the furnace and make sure they are even and straight. Also sight down the roller rails and make sure the furnace rails match the height of the elevator rails and that the outer vestibule rails are also at this height.

Go into the furnace and make sure all rollers can turn freely. A roller that is ‘dragging’ can cause a load to require a higher than normal amount of force to move, potentially causing a clutch to trip.

Check the chain guides. Warped or misaligned chain guides can cause a chain or handler to stick, potentially causing a clutch to trip.

Check the trays. Old warped or broken trays can cause a hangup just as easily as warped roller rails and chain guides. Old trays should be periodically replaced.

What causes oxide on parts?

Oxide on parts generally comes from the part seeing air at too high of a temperature. The most common cause of this is an air leak in the vestibule. The furnace should be brought down and the smoke test procedure followed.

If the oxide can be wiped off, it could be that the parts are being removed from the furnace at a temperature that is too high. Consider a longer quench cycle.

Oxide can also be deposited in the furnace from a water leak, if a water-cooled jacket is present or from a burner leak if there is a crack in a radiant tube.

Why won’t the doors open during a cycle? How do you bypass the inner locks?

There are many reasons why an inner door could be locked out. It is typically one of the following:

- The elevator is either not all the way up or down

- The agitators are not on

- The oil level is low

- The oil temperature is too high

- The vestibule door is open

- The atmosphere switch is in the on position, but atmosphere is not flowing

Newer furnaces will have a furnace door bypass switch to allow you to operate the door. Older furnaces will require an electrician to temporarily bypass the door lockout for maintenance purposes.

What causes carbon control issues?

There are a number of things that can cause carbon control issues. Some of the common ones are as follows:

The most common cause of carbon control issues is a furnace that need to be burned out. Follow the burnout procedure specific to your furnace in your operating instructions. Contact Surface if you need a copy.

Next, consider the condition of the radiant tubes. A carbon level that varies with the burner high fire cycle can indicate a crack in a radiant tube or faulty burner packing.

Varying carbon levels can be caused by a misadjusted loop controller. Try placing the controller in manual control mode and leaving the percent output at a fixed value to see if the carbon then stays steady.

Carbon issues can be caused by an air or water leak. Try performing a leak test using the leak test procedure for your specific furnace in the operating instructions. Consult Surface if you need a copy.

If a leak can not be found, shut off all air and gas enrichment and let the furnace idle at temperature with endothermic gas only for 4-6 hours. The dew point in the furnace should come fairly close to the dew point of the generator gas. Otherwise there is a leak is the system somewhere.

A poorly fitting inner door can be a source of carbon control issues. Degas the vestibule only and leak the furnace gassed. Looking into the vestibule at the inner door, there should be a healthy flame along the bottom of the door and ideally no flame at all at the top, along the arch.

A damaged atmosphere inlet pipe can cause issues. Inspect the atmosphere inlet pipe.

Nitrogen Methanol using furnaces could have a clogged or damaged sparger. Try cleaning and inspecting the sparger.

How do you do a carbon burnout on an Allcase furnace?

Always follow the procedure recommended in your furnace operating instructions. Contact Surface Combustion if you need a copy of these.

How do you leak test an Allcase furnace?

Consult the leak test procedure in your furnace operating instructions. Contact Surface if you need a copy.

What industries typically use batch integral quench furnaces?

BIQ furnaces are used across numerous industries including automotive, aerospace, agriculture, hand tools, mining, heavy equipment, powder metal manufacturing, and general commercial heat treating.

Can these furnaces meet automotive quality standards?

Yes, properly equipped and maintained BIQ furnaces can meet automotive quality standards including CQI-9 requirements when paired with appropriate instrumentation and controls.

How do I ensure consistent case depth in carburized parts?

Consistent case depth requires precise control of temperature, atmosphere carbon potential, and cycle time. Modern furnace controls maintain these parameters within tight tolerances, and regular verification through metallurgical testing ensures consistency.

Can batch integral quench furnaces meet aerospace specifications?

Yes, BIQ furnaces with appropriate instrumentation, controls, and qualification can meet aerospace specifications for many heat treating processes. Class 2 and higher instrumentation can be provided for AMS compliance.

Standard Sizes

| Width | 24″ | 30″ | 36″ | 36″ | 36″ | 42″ |

| Length | 36″ | 48″ | 48″ | 72″ | 72″ | 72″ |

| Height | 24″ | 30″ | 36″ | 36″ | 42″ | 42″ |

Maximum operating temperatures up to 1950°F

Multiple gas fired heating systems available including vertical and horizontal radiant tube configurations.

Electric heating systems available including Proletric® style and canned element style

Roller rail or skid hearth systems

Oil, water, polymer, and brine quench systems available

Atmosphere Cool Chambers (Top Cool) available

Numerous automation and networking controls available

Allcase® family also includes RTB (Radiant Tube Box) and ACT (Radiant Tube Box Furnace with Atmosphere Top Cool)

Proprietary VF™ fan extends fan life by minimizing vibration and gives uniform atmosphere distribution

Annealing

Black Oxide

Carbon Restoration

Carbonitriding

Carburizing

Ferritic Nitrocarburizing (FNC)

Hardening

Marquenching

Normalizing

Solution Treatments

Spheroidizing

Stress Relieving

Partial processes list shown. Looking for something specfic, contact us.

Aerospace

Agricultural

Aluminum Processing

Automotive

Bearings

Castings

Commercial Heat Treating

Fasteners

Forging

Gears

Government Furnace Supplier

Hand & Power Tools

Off Road/Mining/Excavation

Oil & Gas

Powder Metals

Sporting Goods

Trucking/Bus/Rail

Wind Power

Partial industries list shown. Looking for something specfic, contact us.

Aerospace Components

Bearings

Cast and Ductile Iron

Casting

Chain

Copper

Crankshafts

Cutlery

Fasteners

Forgings

Gears

Gun Barrels

Hand Tools

Pinions

Powdered Metal

Rock Bits

Shafts

Springs

Stainless Steels

Steel

Tool Steels

Tools

Partial material and component list shown. Looking for something specfic, contact us.

Temper

Atmosphere Generator

Air Cool Station

Atmosphere Cooling Systems

Control Systems for Industrial Heat Treat Furnaces

Uni-DRAW® Batch Tempering Furnaces

Trays/Baskets/Fixtures

Loading Cars

Load/Unload Tables

Partial companion equipment list shown. Looking for something specfic, contact us.

Surface® is Your Source

CONTACT US TODAY, and let us show you the Value of Surface™